All Posts

Written by Ben Jennings, P.E.

The number of Electric Vehicles (EV’s) on the road is ever increasing. As such, so are the number...

Written by Ground Sun UK

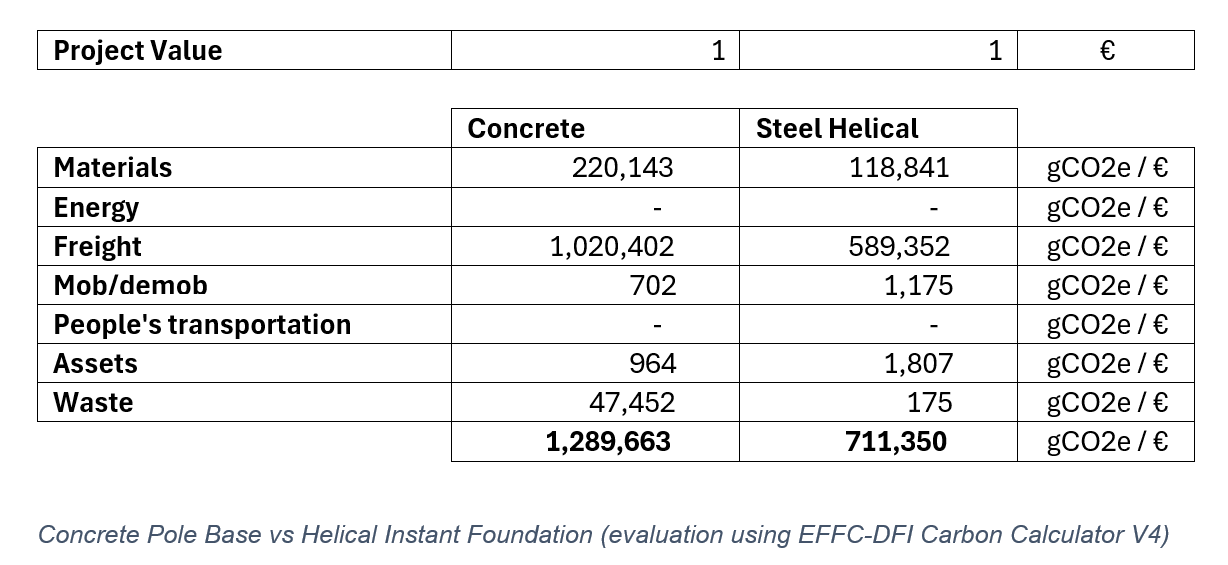

A £7.5m water treatment infrastructure project was being constructed in Staffordshire, UK. Access...

Written by Gary L. Seider, PE

Since the mid 1990’s, Hubbell Power Systems, Inc. has held an ICC-ES Evaluation Report for several...

Written by Foundation Technologies, Inc.

A large brownfield site stood three blocks from the center of Hartsville, South Carolina....

Written by Gary L. Seider, PE

When installing a helical pile foundation, the installing contractor is responsible for inspection...

Written by Chance Foundation Solutions

From "Preservation of Historic Structures Using Screw-Pile Foundations" by Dr. Alan J. Lutenegger,...

Written by Shawn Downey

The foundation required to support a monopole is primarily a moment foundation, supporting an...

Written by Brent Adams

While small when compared to a large building or structure, light duty monopiles can be easily...

Written by Jason Herron, PE, CWI

For new construction applications machinery such as mini-excavators, standard excavators, backhoes,...

Written by Chance Foundation Solutions

One Richmond Row, a 32-storey apartment tower rising in London, Ont., will soon be the tallest...

Written by Chance Foundation Solutions

Telephony in Centralia Centralia was one of the first of the smaller towns of Missouri to have an...

Written by Chance Foundation Solutions

The Chance Civil Construction team has created a guide to introduce students to the basics of...

Written by Chelsea Kiesling

Historic buildings provide a window to the past allowing us to explore our history and appreciate...