A sturdy, level base should support an EV charger and easily accommodate the conduit required to power it. Falling prey to the “that’s how we’ve always done it” mantra, many installers are still utilizing the tedious auger and concrete method, but there’s a better way. Helical piles are an excellent choice for foundations of Electric Vehicle (EV) Charging Stations. Made from steel, these foundations can be easily screwed into the ground using common construction equipment and immediately loaded.

Learn more about Chance helical foundations for EV charging infrastructure:

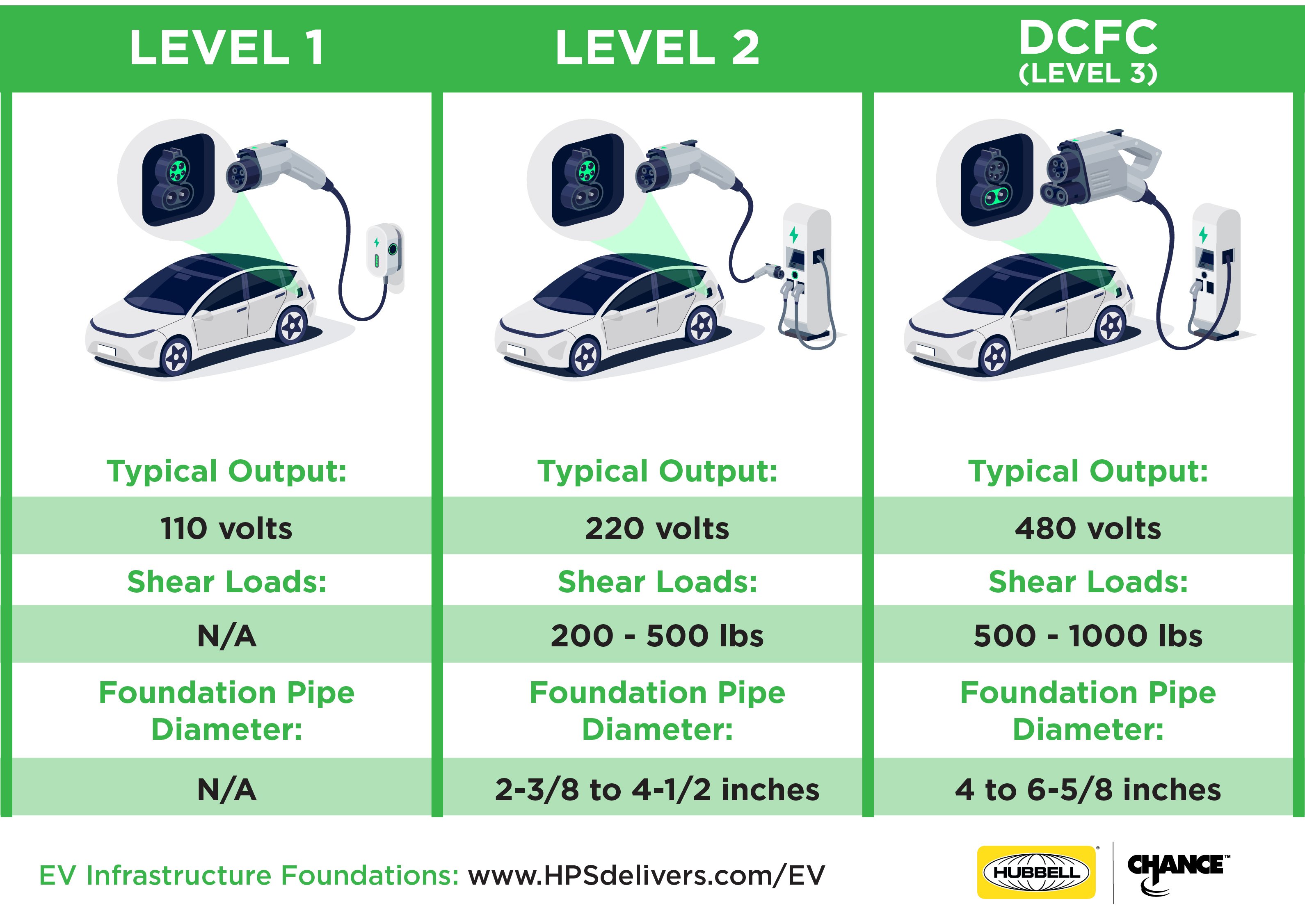

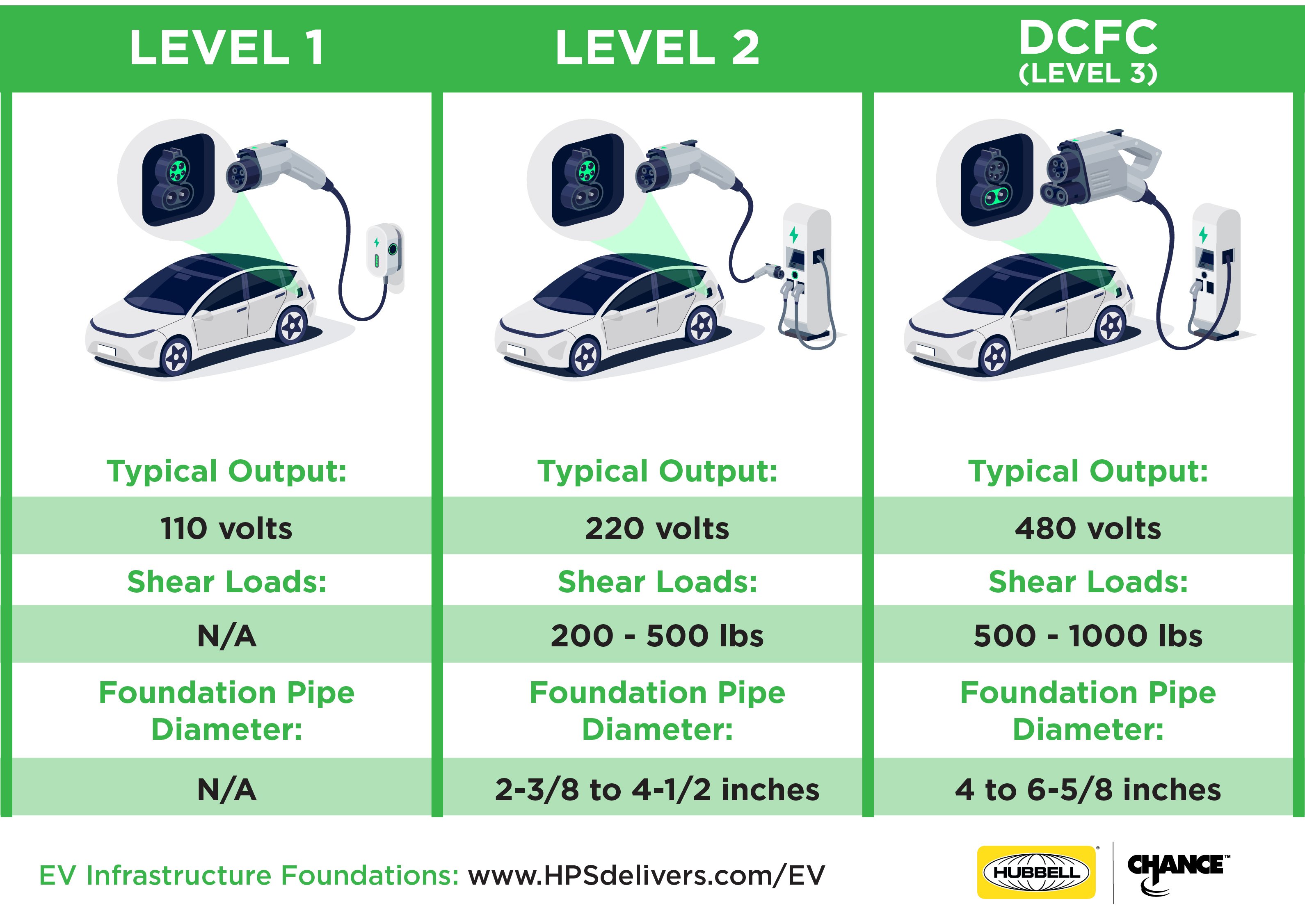

In the current EV market, there are three different levels of charging stations being widely used. These levels include Level 1, Level 2, and Direct Current Fast Charger (DCFC or sometimes called Level 3). Of these three levels, Level 2 and DCFC are commonly used in commercial applications that utilize Helical Piles.

Level 1 chargers are wall mounted units or power cords that function on a standard output of 110 volts with a charge time of 24 to 48 hours. Level 1 chargers are used for residential or personal charging applications where a vehicle can be parked for an extended period. Due to their small size Level 1 will typically not require a dedicated foundation for use.

Level 2 chargers are what most individuals think of when they picture an EV Charging Station. In appearance they typically have a similar look to a standard gasoline pump but much smaller. They typically have between 1 to 4 charging cords with an output of 220 volts and charge time of 4 to 8 hours. This type is the most common for commercial applications and multiple chargers are spaced between parking lots in shopping centers or EV charging specific parking lots. The weight of Level 2 chargers is relatively light, usually weighing a couple hundred pounds at most. A single 8-inch or 10-inch diameter helix plate attached to a pipe shaft and screwed into the ground is adequate to resist the weight of the charger in soil bearing. The controlling factor for foundation design is the lateral shear load developed from wind. Typical shear loads on these structures are between 200 to 500 lbs., which in turn develop between 500 to 1500 ft-lbs. of groundline moment. These lateral loads can easily be resisted with small diameter pipe shaft helical foundation systems with diameters ranging from 2-3/8 inches to 4-1/2 inches. The length of the foundation will vary based on soil shear strength, frost depth, and water table. Typical design depth for application is between 4 to 10 feet. EV Charger Foundations may or may not feature a cableway slot for underground conduit and wiring depending on the specific design of each EV Charging Station. If a cableway slot or hole is required, the minimum pipe shaft diameter recommended is 4 inches. This is to maintain adequate steel to transfer shear and bending moment to the soil and adequate torsional strength for installation.

DCFC (or Level 3) chargers are less prevalent than Level 2, but charge at a much more expedient rate that allows EV vehicles to be charged in under 1 hour. Their lesser prevalence is mainly due to their size and energy requirement of 480 volts. Infrastructure and grid capacity to service numerous DCFC chargers is not currently available in most areas. A DCFC charger either have a larger gasoline pump appearance, like that of Level 2, or is tall and rectangular shaped resembling a large vending machine. Other infrastructure such as transformers, cabinets, and switchgears may be required depending on the available power service near the charger. Smaller gas pump style DCFC units may only weigh a few hundred pounds, but larger rectangular units may weigh over 1000 pounds. The higher weight may require a larger helix plate than a Level 2 charger with diameters ranging from 10-inch to 16-inch. As with Level 2 chargers, shear loads are the main controlling factor of design. Lateral load resistance can be developed by either the use of larger pipe shaft diameters or shear vanes. Typical pile diameters for DCFC are 4 inches to 6-5/8 inches with design depths of 5 to 15 feet. Due to the larger footprint of the large rectangular DCFC charger, it may be necessary to add a second helical pile foundation for stability and serviceability reasons. Cableway slots are common with DCFC chargers and may be much larger than that of Level 2. Cableway slots of up to 3-inches in width are achievable with a 6-5/8 diameter shaft. Wider cableway slots may require a larger diameter shaft to maintain structural shear and bending moment capacity.

| Foundation Type |

Typical Output |

Shear Loads |

Foundation Pipe Diameter |

| Level 1 |

110 volts |

N/A - No foundation required |

| Level 2 |

220 volts |

200 - 500 pounds |

2-3/8 to 4-1/2 inches |

| DCFC |

480 volts |

500 - 1000 pounds |

4 to 6-5/8 inches |

Helical piles are an excellent foundation system for EV Charging Stations. The top plate can be adapted to suit numerous bolt circles and connections available from the various EV Charging Station Manufacturers. Installation torque for these types of foundations is typically less than 10,000 ft-lbs., so smaller equipment can be utilized for installation. Chance EV foundations are also more eco-friendly than traditional concrete foundations - not only in the lower emissions required for installation, but the steel foundations are made from recycled steel and are reusable and recyclable.

As infrastructure is upgraded, technology evolves, and EV systems will also change. The modularity and customizability of helical piles will always be a great foundation option for engineers to consider.

Contact civilconstruction@hubbell.com for more information or to receive a quote.