Buckling of Helical Piles

Buckling occurs when a long slender object in compression deflects perpendicular to the axis of loading somewhere along its length. The best way to visualize buckling is with an example. If an individual was to take a swimming pool noodle, grab both ends and then push the ends together, what happens to the noodle? It bends in the middle as the two ends come closer together. When a helical pile buckles, the pile behaves just like that pool noodle - the shaft in the middle deflects laterally.

Buckling occurs when a long slender object in compression deflects perpendicular to the axis of loading somewhere along its length. The best way to visualize buckling is with an example. If an individual was to take a swimming pool noodle, grab both ends and then push the ends together, what happens to the noodle? It bends in the middle as the two ends come closer together. When a helical pile buckles, the pile behaves just like that pool noodle - the shaft in the middle deflects laterally.

The most important characteristic to remember with buckling is that it only happens when the pile is in compression. If the load on the pile is in tension (pulling on the pile), the section will never buckle. Buckling capacity is the amount of load that can be placed on a pile before it buckles.

What Goes into Determining the Buckling Capacity of Helical Piles?

There are many pile properties that affect the buckling capacity of a helical pile. The first is the soil conditions. When the Standard Penetration Test (SPT) blow count of a soil is greater than 4, the pile shaft is assumed fully supported and buckling does not occur. The soil restrains the pile shaft and ensures it cannot move laterally. However, when the soil blow count is 4 blows or less, the pile can buckle, but the soil will still provide some lateral resistance. This results in the buckling capacity in this type of soil to be greater than in air or water, but less than when fully restrained in firm soil.

Another property that affects buckling capacity is the pile cross section. Piles with higher moments of inertia will have higher buckling capacities. Even if piles have the same cross-sectional area, the pile with higher moment of inertia will have greater buckling capacity.

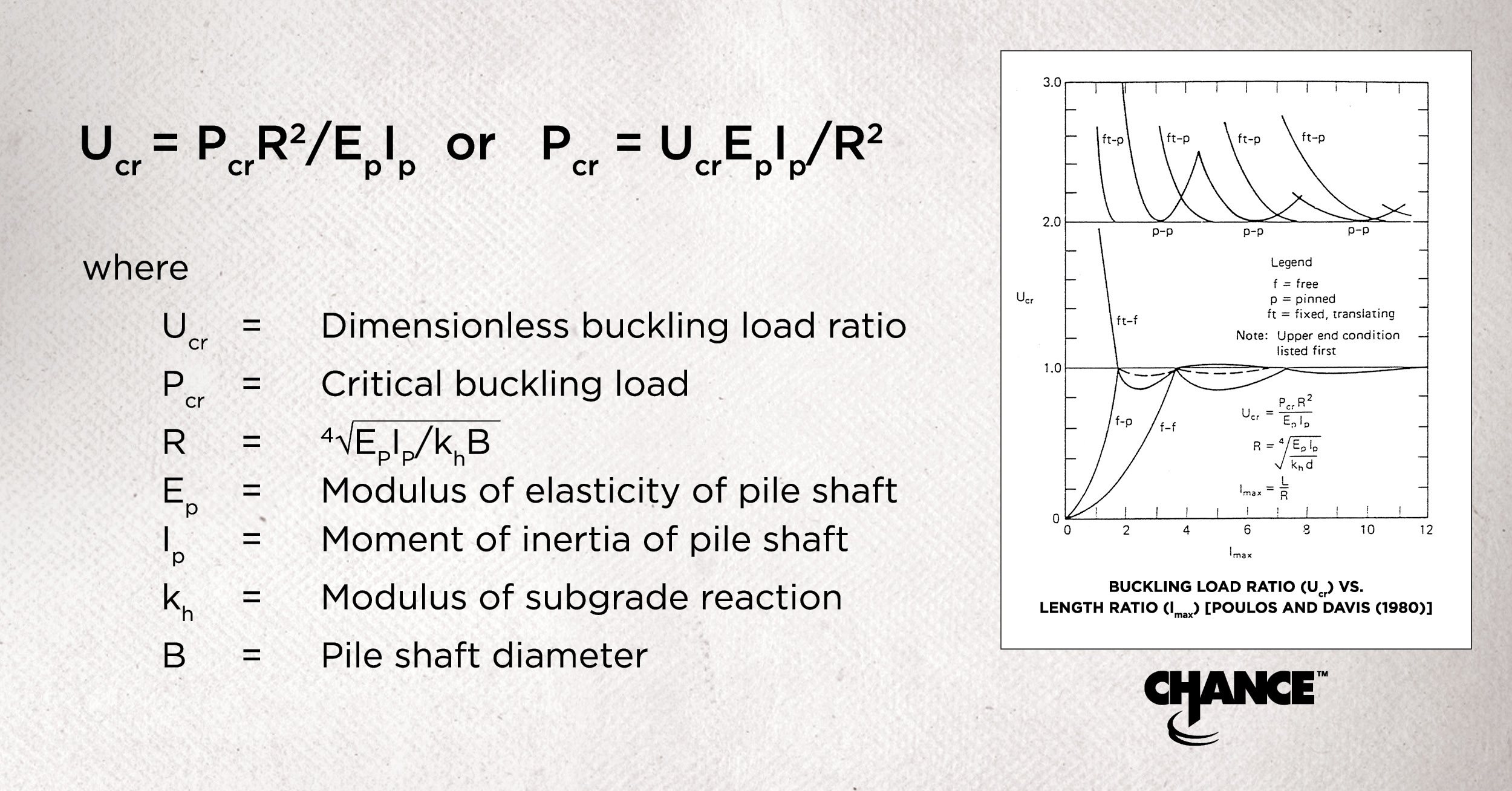

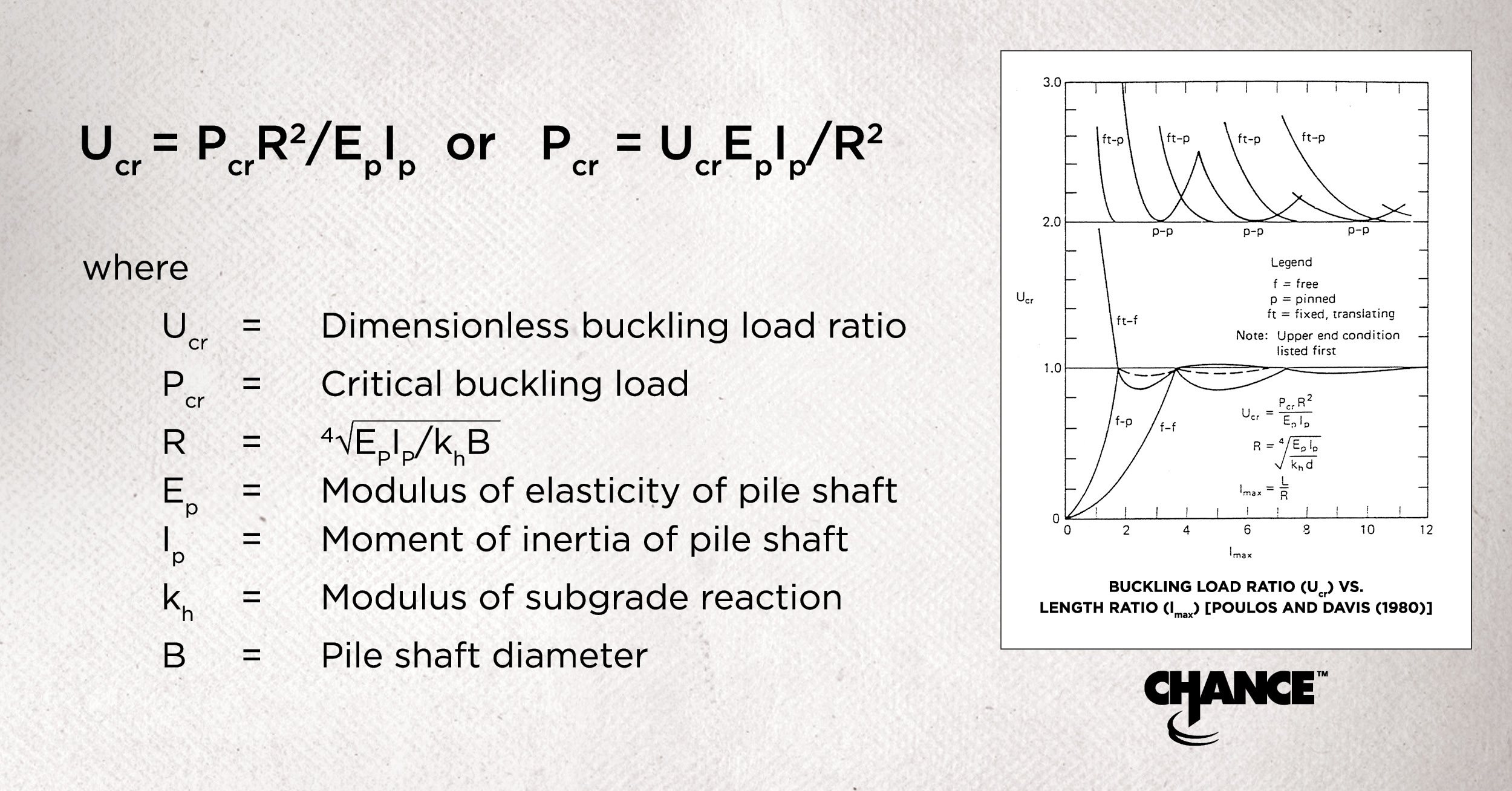

Calculations to Use to Calculate Buckling Capacity

There are many methods to calculate the buckling capacity of a steel pile. The best method for use when piles are completely embedded below the soil surface is the Davisson Method. This method considers the added lateral restraint of the soil. See section 5.8.5 of the CHANCE Technical Design Manual for more information on the Davisson Method.

If a pile has reveal height above the soil surface, the Euler Buckling calculation is the best option. These are the typical calculations used by the Steel Design Manual for calculating the buckling capacity of members.

What to do when Buckling is a Concern

There are a few options that can increase the buckling capacity of a pile. The easiest is to just increase the moment of inertia of the pile. If a CHANCE Type RS3500 3-1/2” OD pipe shaft is not large enough, try calculating the buckling capacity using CHANCE Type RS4500 4-1/2” OD pipe shaft. Similarly, adding grout to a square shaft helical pile will increase the OD of the shaft which in turn will increase the moment of inertia of the cross section. A pulldown pile around a square shaft can add significant amounts of lateral capacity. Even adding grout to the ID of a pipe shaft can sometimes add enough flexural rigidity to keep the pile from buckling.

A good compromise to address buckling in soft/loose soils is to use helical combination piles, or combo piles for short. A combo pile consists of a square shaft lead section and round shaft (pipe) extension sections.

Additional information about buckling and the calculations mentioned can be found in section 5.8 of the Chance Technical Design Manual.