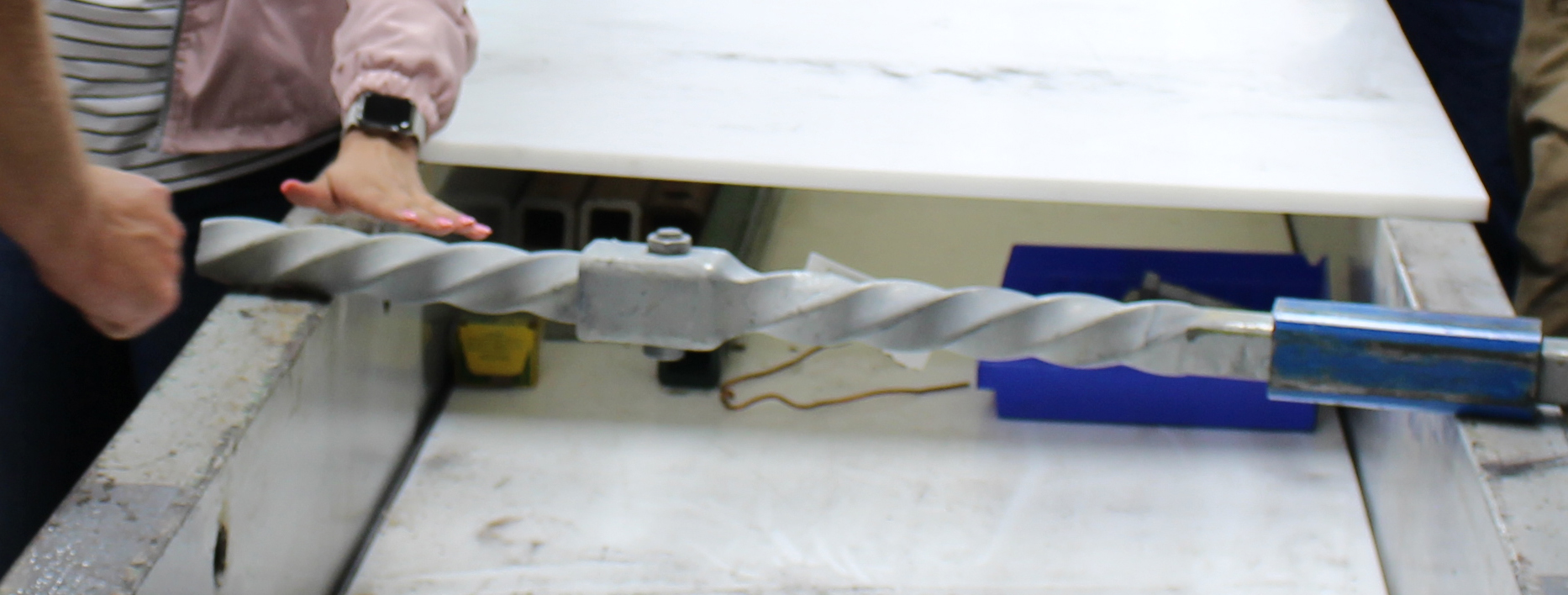

Torque

Written by Jason Herron, PE, CWI

For new construction applications machinery such as mini-excavators, standard excavators, backhoes,...

Written by Gary L. Seider, PE

In short, soil type and strength matter a lot! In this article about installation requirements, I...

Written by Gary L. Seider, PE

Chance Instant Foundations are a popular foundation option for any pole based application that...

Written by Garrett Hubbell, P.E.

Ashland sits in the foothills of the Siskiyou and Cascade mountain ranges in southwest Oregon. A...

Written by Ian Romain, P.E.

It is very important to consider both the site subsurface soils and the applied loads when...

Written by Gary L. Seider, PE

We’re often asked by engineers and contractors how to bid helical pile foundations. This often...

Written by Nate Seguin, PE

The Reality A recognized challenge for geotechnical engineers designing deep foundations is...

Written by Brent Adams

All Engineers can relate to an experience we’ve had where what we designed was not how it turned...

Written by Josh Lindberg

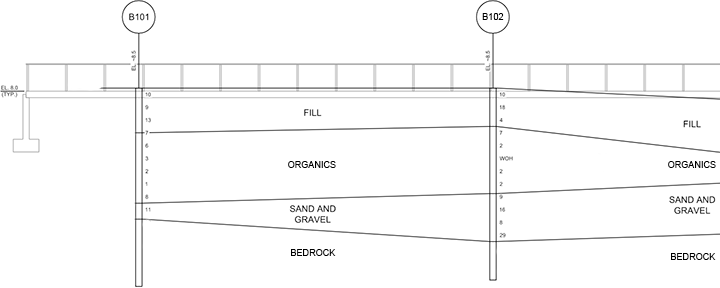

On many construction projects, soil borings are not completed due to the property owner wanting to...

Written by Gary L. Seider, PE

The load capacity of helical piles can be determined 3 ways. The method(s) used are dictated by the...

Written by Gary L. Seider, PE

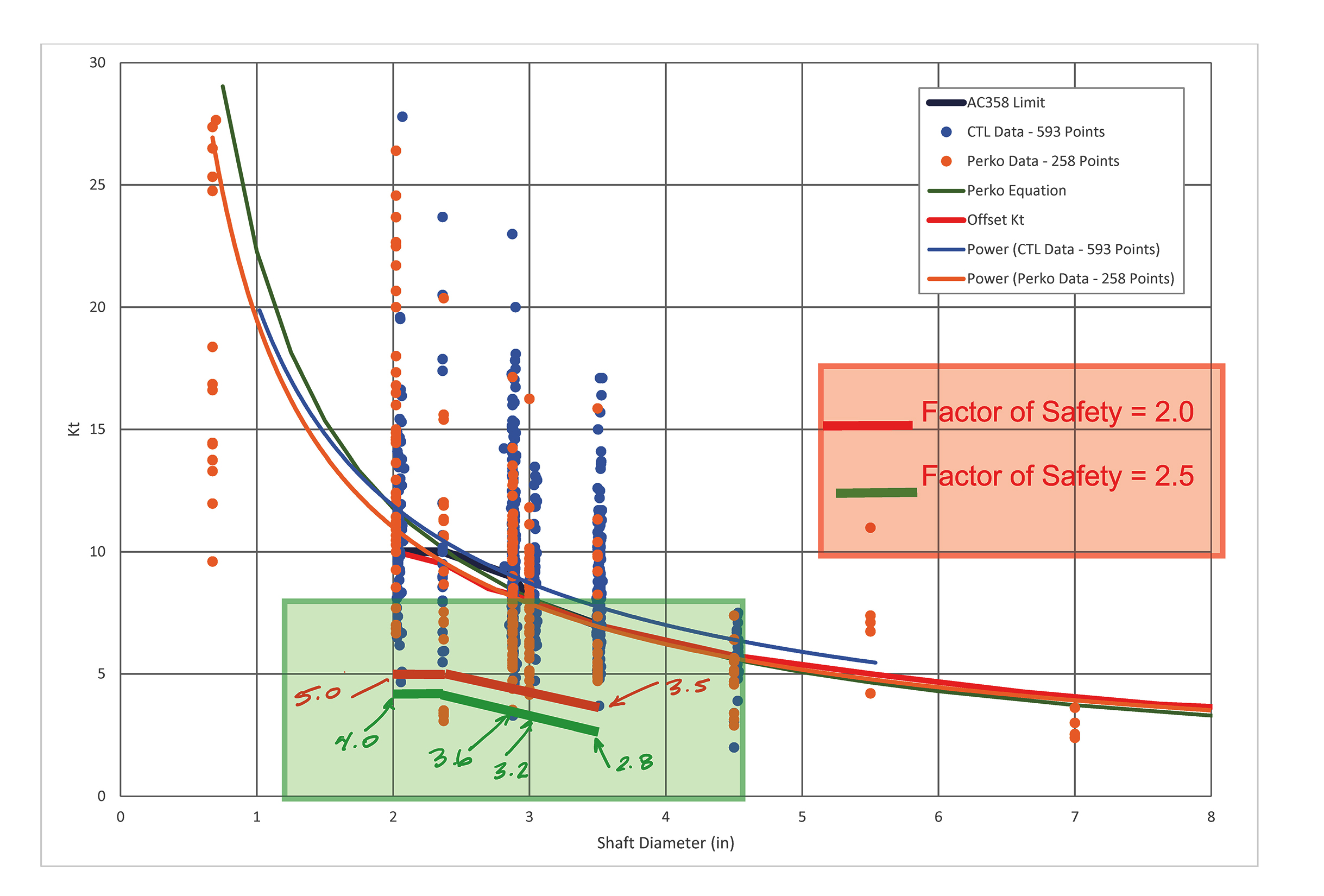

Today, it is generally accepted that installation torque can be used to verify the axial capacity...

Written by Shawn Downey

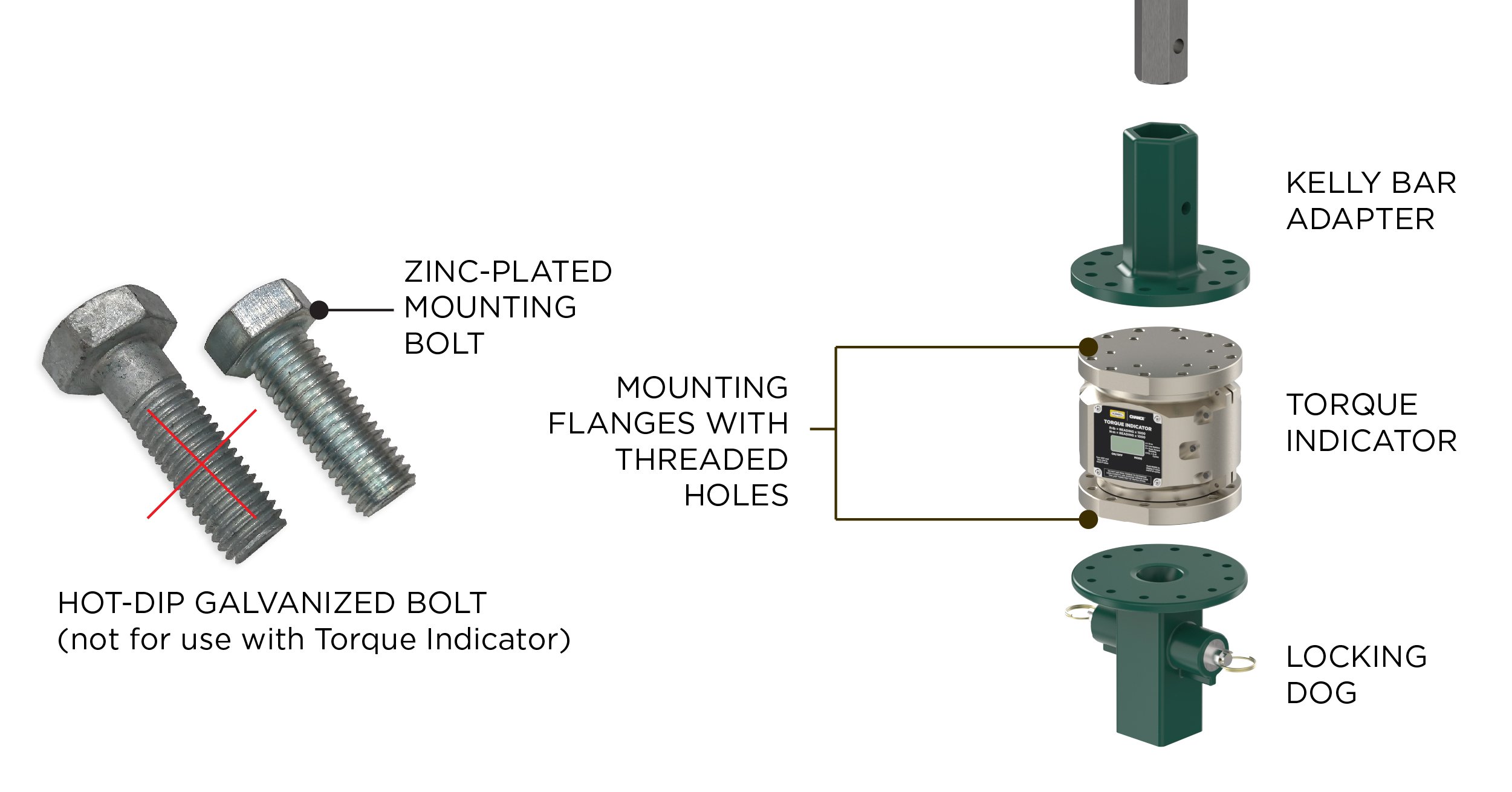

There is no equivalent for measuring torque directly in the tooling string. Using differential...

Written by Gary L. Seider, PE

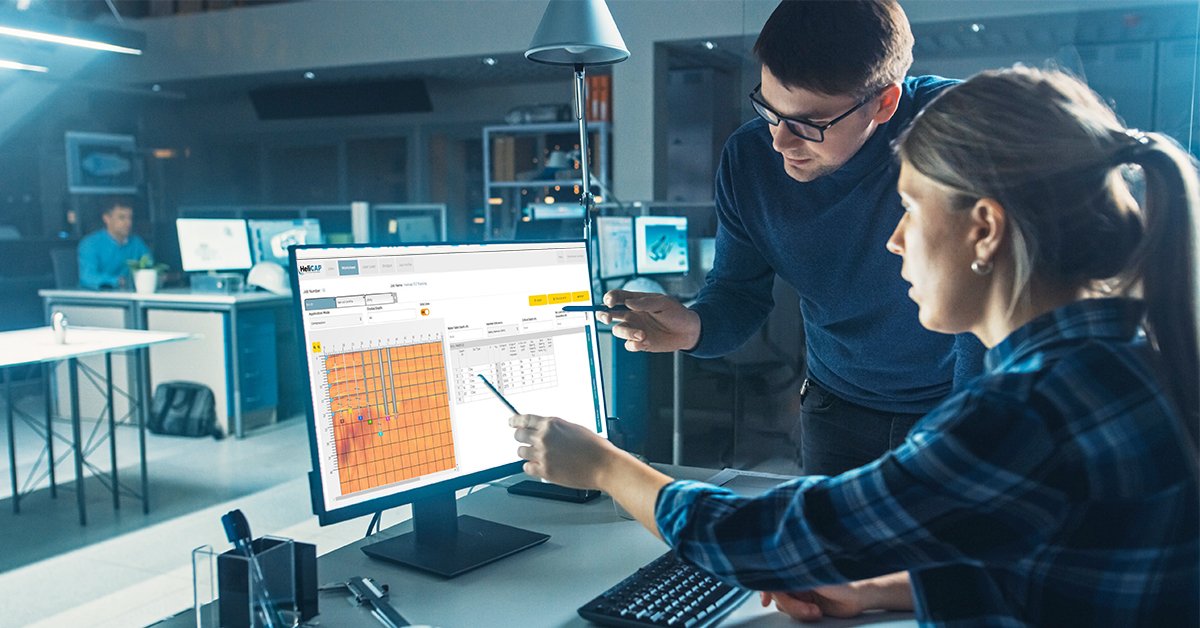

Capacity-to-torque relationships for helical piles are used frequently to determine termination...