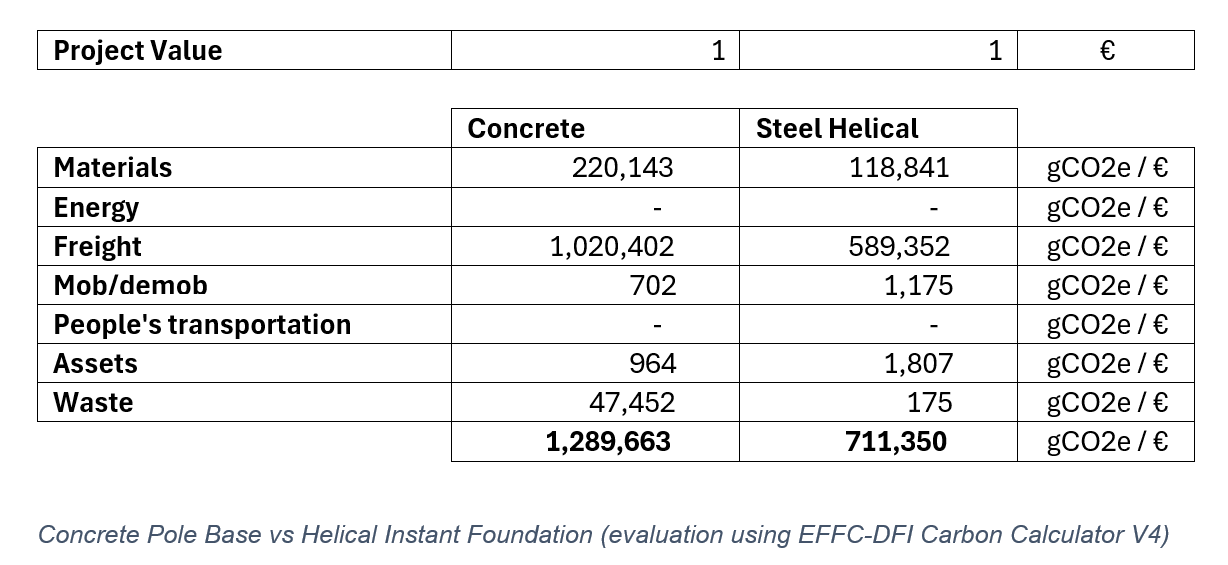

While small when compared to a large building or structure, light duty monopiles can be easily overlooked for sustainable evaluation. However, the potential aggregate impact can be quite sizable. A recent carbon calculation for two types of foundation technologies - a pre-cast concrete pole base and a steel pole base foundation - for an outdoor lighting application show that there is a potential carbon impact span from 1.4 ton to 0.8 ton carbon dioxide equivalent (CO2e) depending on the technology selected. According to the Environmental Protection Agency (EPA), CO2e refers to “the number of metric tons of CO2 emissions with the same global warming potential as one metric ton of another greenhouse gas.”

Carbon Calculation: Concrete vs. Steel

The European Federation of Foundation Contractors (EFFC) and the Deep Foundations Institute (DFI) have cooperated to create a tool which calculates the carbon dioxide emissions of foundation and geotechnical works. This allows users to be able to calculate the carbon impact of their designs/plans.

Learn more about the EFFC/DFI Carbon Calculator and download the latest version.

Following is a comparison of the two solutions using the EFFC/DFI Carbon Calculator

|

Project Value

|

1

|

1

|

€

|

| |

|

|

|

| |

Concrete

|

Steel Helical

|

|

|

Materials

|

220,143

|

118,841

|

gCO2e / €

|

|

Energy

|

-

|

-

|

gCO2e / €

|

|

Freight

|

1,020,402

|

589,352

|

gCO2e / €

|

|

Mob/demob

|

702

|

1,175

|

gCO2e / €

|

|

People's transportation

|

-

|

-

|

gCO2e / €

|

|

Assets

|

964

|

1,807

|

gCO2e / €

|

|

Waste

|

47,452

|

175

|

gCO2e / €

|

| |

1,289,663

|

711,350

|

gCO2e / €

|

Concrete Pole Base vs Helical Instant Foundation (evaluation using EFFC-DFI Carbon Calculator V4)

According to the International Energy Agency, lighting accounts for about 5% of greenhouse gas emissions worldwide. Unfortunately, most of the sustainability conversation around the approximately 50 million existing streetlights in the United States focuses on modernizing the lighting fixtures. However, the cost to manufacture, transport and install lighting foundations are largely overlooked in the conversation.

Magnitude of Carbon Impact for New Streetlight Installation

Consider the potential carbon impact of just new streetlight assembly due to real estate development. Even municipalities that may not be considered a congested urban environment can be significantly impacted if individual additions are not considered as a collective. Idyllic areas such as Boise, ID estimate that they install about 300 new street lights a year. This could inadvertently add 300 tons of carbon into the environment – now scale that impact on other areas in the country where even more land development/construction is occurring!

Another aspect to consider for this “sneaky” carbon impact is the targeted 500,000 EV Chargers by 2030 which will use similar foundation technologies. Even if conservative estimates of installations are used, the potential aggregate carbon impact is significant.

Chance helical piles are made from steel, a highly recyclable material. If needed, the foundations can be removed and reused, which has been successfully done even after 25 years underground! One of the largest Chance foundations for pole bases weighs only 404 pounds. A comparable concrete base could weigh over 10,000 pounds. The freight difference alone is staggering! Learn more about the environmental benefits of Chance foundations by visiting our Green Building webpage.

Conclusion

The challenge is recognizing that although these small installations do have a major influence on carbon release when considered together. Fortunately, most of these “paper cut” emissions can be mitigated by making sure your specifications call out sustainable solutions for EACH installation.

Contact us if you have any questions or are ready to start looking “below the bulb” for a more sustainable future.