Hot line maintenance began when disconnect sticks were first used to open energized disconnect switches. Even though this operation proved that long, dry poles could be equipped with fittings which would enable linemen to work with safety on energized lines, many years passed before enough interest was aroused in the hot line idea to use these tools for any operation other than opening switches.

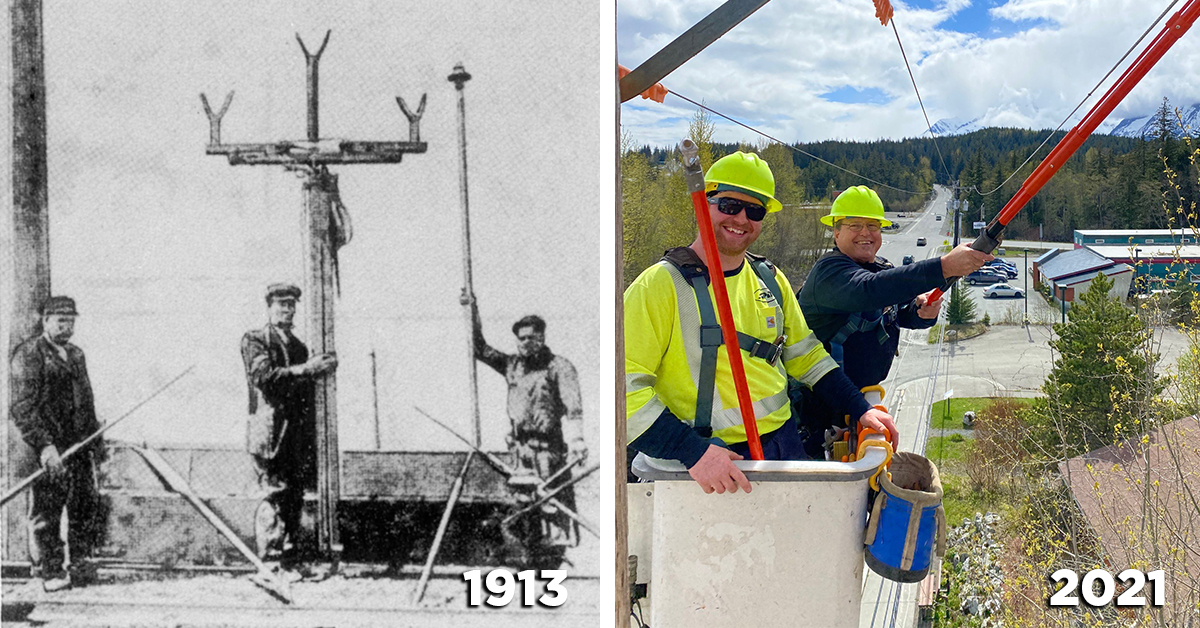

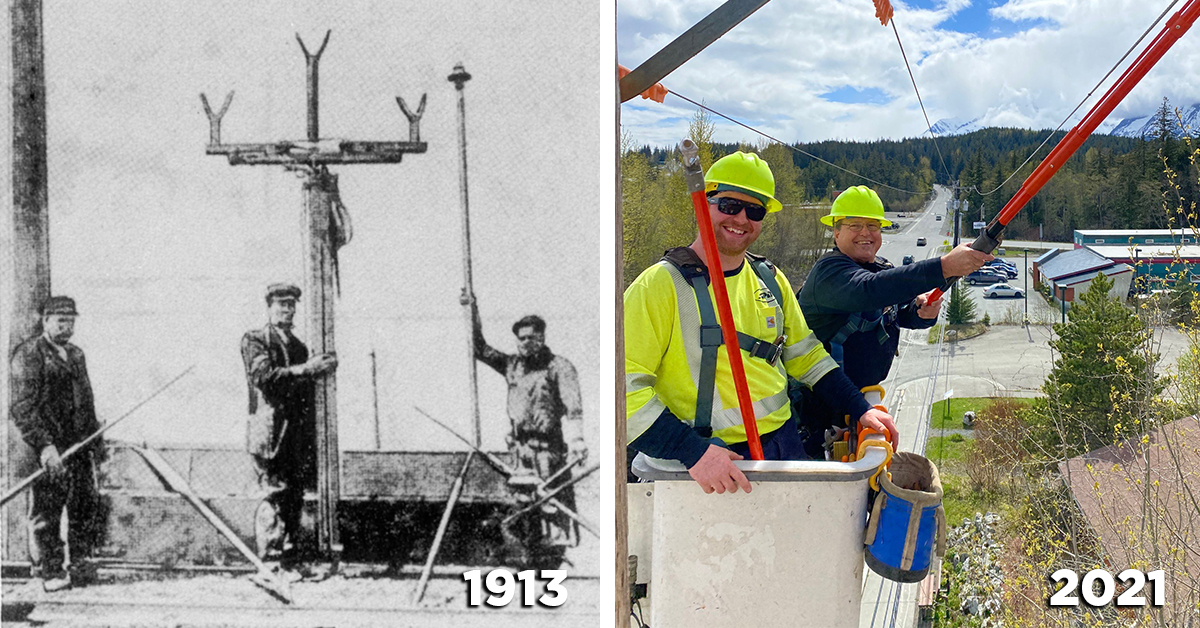

While the use of hot line maintenance tools is sometimes considered a recent development in the electrical power industry, forerunners of modern hot line tools made their appearance as far back as 1913. The earliest available picture of these tools is the accompanying photograph taken in 1914.  These initial tools were homemade from wood. The natural properties of the wood made them highly susceptible to outside factors such as dirt, impacts, and most importantly, moisture. As a result, the tools had to be replaced frequently; however, these crude and bulky tools sparked the development of our present efficient and refined tools. In almost every case, it was the linemen who prompted development of the various hot line tools which eventually led to the present universal practice known as "hot line maintenance."

These initial tools were homemade from wood. The natural properties of the wood made them highly susceptible to outside factors such as dirt, impacts, and most importantly, moisture. As a result, the tools had to be replaced frequently; however, these crude and bulky tools sparked the development of our present efficient and refined tools. In almost every case, it was the linemen who prompted development of the various hot line tools which eventually led to the present universal practice known as "hot line maintenance."

Also, as line voltages began to increase, requiring heavier conductors, support devices, and longer minimum approach distances, the wooden poles had to be larger and heavier as well, making them more difficult to handle. CHANCE first introduced fiberglass tools to the market in 1957 to address these issues. Compared to the wooden versions, the new fiberglass poles were lighter, stronger, more durable, and had superior hydrophobic (water-repelling) properties for working under wet conditions. Since their introduction, CHANCE has continued to work closely with line maintenance operators to develop and improve tools and techniques that utilize Fiberglass-Reinforced Plastics (FRP) technology, many of which are still in use to this day.

Hotstick Manufacturing

There is a common characteristic among a wide range of CHANCE® Lineman Grade Tools™. Whether it’s hoist links, crossarm assists, gins, booms, insulator cradles, universal poles, strain poles, wire tongs, jib extensions, or ladders: they are all designed and built with Epoxiglas® insulated poles.

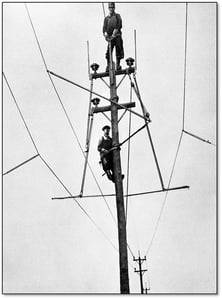

All Epoxiglas® products begin with the creation a closed cell foam core. The closed cell design prevents moisture and other contaminants from getting inside the tool. Next, core sections are bonded together, then pulled through a series of resin tanks, where certified electrical grade fiberglass strands are impregnated with epoxy resin and formed along the core’s length (for bending and tension strength) and wrapped around its circumference (for crush and torsion strength). Finally, the composite matrix passes through a heated die, bonding the outer fiberglass layers to the core. This last step ensures that there are no voids or air pockets between the core and the fiberglass shell, and maximizes the strength and electrical insulating properties of the sections.

All Epoxiglas® products begin with the creation a closed cell foam core. The closed cell design prevents moisture and other contaminants from getting inside the tool. Next, core sections are bonded together, then pulled through a series of resin tanks, where certified electrical grade fiberglass strands are impregnated with epoxy resin and formed along the core’s length (for bending and tension strength) and wrapped around its circumference (for crush and torsion strength). Finally, the composite matrix passes through a heated die, bonding the outer fiberglass layers to the core. This last step ensures that there are no voids or air pockets between the core and the fiberglass shell, and maximizes the strength and electrical insulating properties of the sections.

Standards for Linemen Tools

CHANCE Epoxiglas® products are designed and tested to meet or exceed several different industry standards:

- ASTM F711: FRP Rod and Tube Used in Live Line Tools

- ANSI/IEEE 561: Guide for Maintenance Methods on Energized Power Lines

- IEC 60855: Insulating Foam Filled Tubes for Live Line Work

- IEC 60832: Insulating Poles and Universal Tool Attachments for Live Line Work

- OSHA 1910.269(j)(1)(iii): Occupational Safety and Health – Live Line Tools

- OSHA 1926.951(d)(1)(iii): Safety and Health Regulations for Construction – Live Line Work

To that end, finished Epoxiglas® pole sections are subjected to a battery of quality checks and tests in the factory, including:

- 100% electrical test at 100kV per foot

- Electrical leakage after moisture exposure

- Crush

- Deflection and Cantilever

- Vacuum Wick

- Dimensional

- Bow

The newly formed Epoxiglas® poles are now ready to be cut to size, and used in multiple insulating tool applications.

Epoxiglas poles are a crucial component of CHANCE tools, making them durable and safe. Although extreme care is exercised in the manufacture of hot line tools, a certain amount of care should be used in the protection of these tools in order to have them ready for use at all times. Proper care will not only result in longer life but will result in greater safety and produce added confidence on the part of the line crewman using the tools. Lineman safety has always been our top priority and, therefore, we are committed to providing free resources to ensure that accurate information on safety practices and procedures is available to anyone who needs it.

More Resources

For additional reading on Epoxiglas® products and their applications, click on any of the links below.

For videos on care and maintenance of your hot line tools, check out these videos:

Refinishing & Repair of Epoxiglas® Poles

Wet/Dry Hotstick Tester

If you can’t find the resources you need online, or would like to learn more, contact our team about in-person training or fill out a form to ask us a question.