There is no equivalent for measuring torque directly in the tooling string. Using differential pressure (or pressure drop across the motor) can work if it is properly set up and calibrated, but keep in mind that pressure is being measured, not torque.

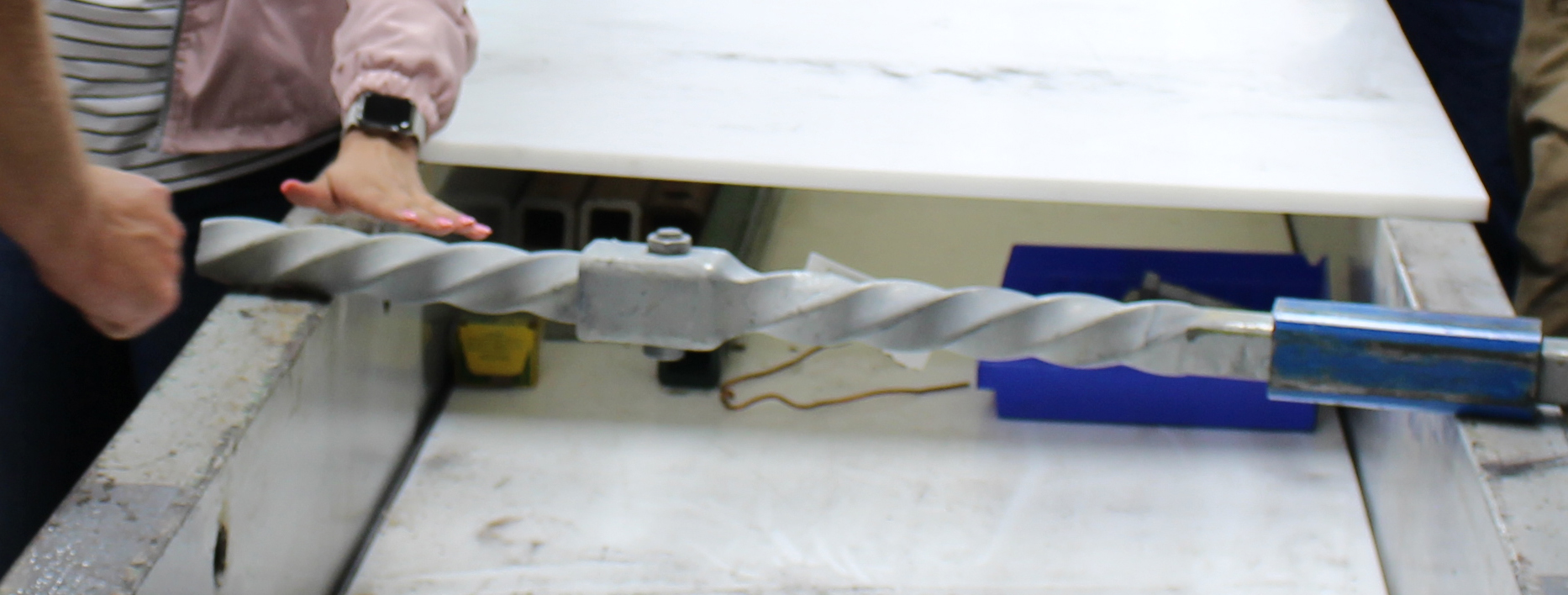

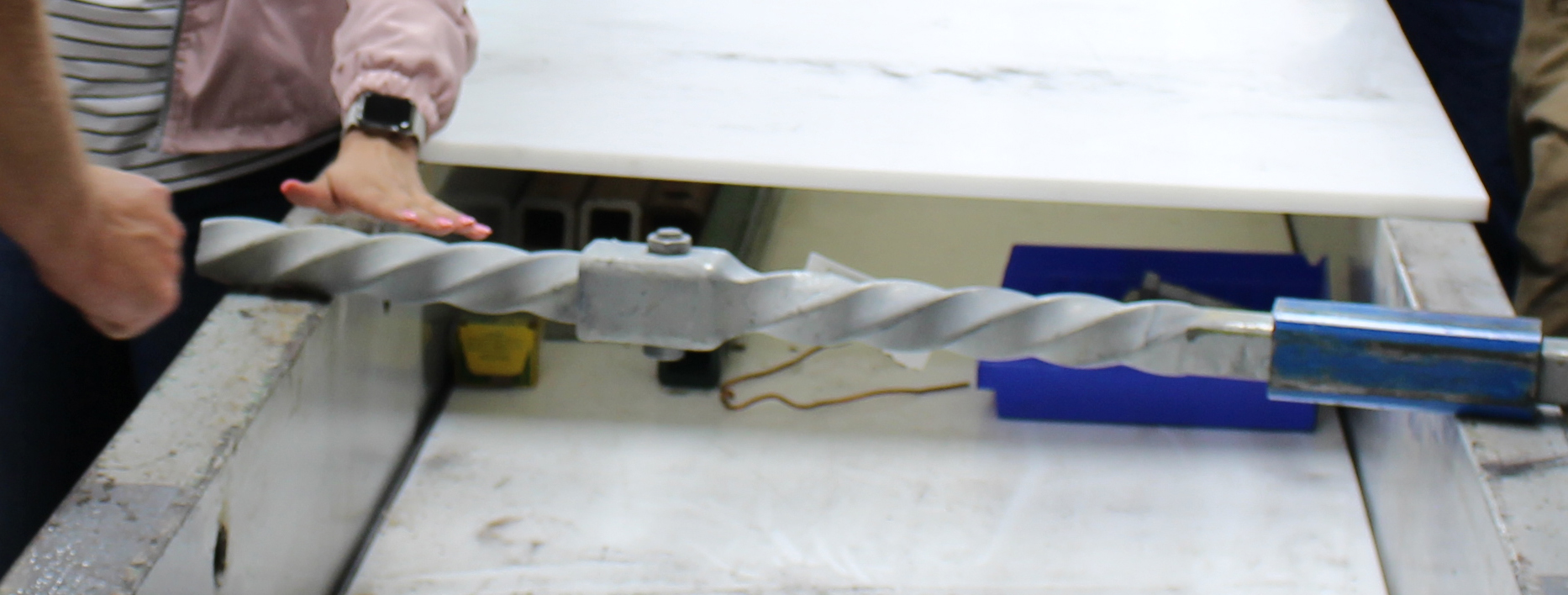

I got a call from a contractor stating there was a material problem with the CHANCE® SS175 helical piles were breaking at 4,000 ft-lb of torque even though they are designed to install at 10,000 ft-lb. When I arrived on site, I concluded that the piles were being over-torqued since there was about 180 degrees of twist per foot of extension. Based on my experience, I estimated that with that much twist the torque reading should have indicated about 12,000 ft-lb. I had a CHANCE Wireless Torque Indicator shipped to the job site with overnight delivery. In the morning, we verified that there was more that 12,000 ft-lb of torque being applied to the SS175 piles. We therefore confirmed that there was not a problem with the material but that the differential pressure indicator by another manufacturer was not providing the contractor with accurate torque readings.

I got a call from a contractor stating there was a material problem with the CHANCE® SS175 helical piles were breaking at 4,000 ft-lb of torque even though they are designed to install at 10,000 ft-lb. When I arrived on site, I concluded that the piles were being over-torqued since there was about 180 degrees of twist per foot of extension. Based on my experience, I estimated that with that much twist the torque reading should have indicated about 12,000 ft-lb. I had a CHANCE Wireless Torque Indicator shipped to the job site with overnight delivery. In the morning, we verified that there was more that 12,000 ft-lb of torque being applied to the SS175 piles. We therefore confirmed that there was not a problem with the material but that the differential pressure indicator by another manufacturer was not providing the contractor with accurate torque readings.

There really is no equivalent for measuring torque directly in the tooling string and the CHANCE Wireless Torque Indicator made by Hubbell Power Systems does just that.

Does your CHANCE Torque Indicator need calibration? Click here to find out.