It is very important to consider both the site subsurface soils and the applied loads when selecting the most effective size/configuration helical pile. Helical piles are installed to a specified minimum torque, based on required axial capacity or resistance. The well-documented torque correlation is the 2nd method to determine ultimate capacity discussed in the International Building Code (IBC) Section 1810.3.3.1.9.

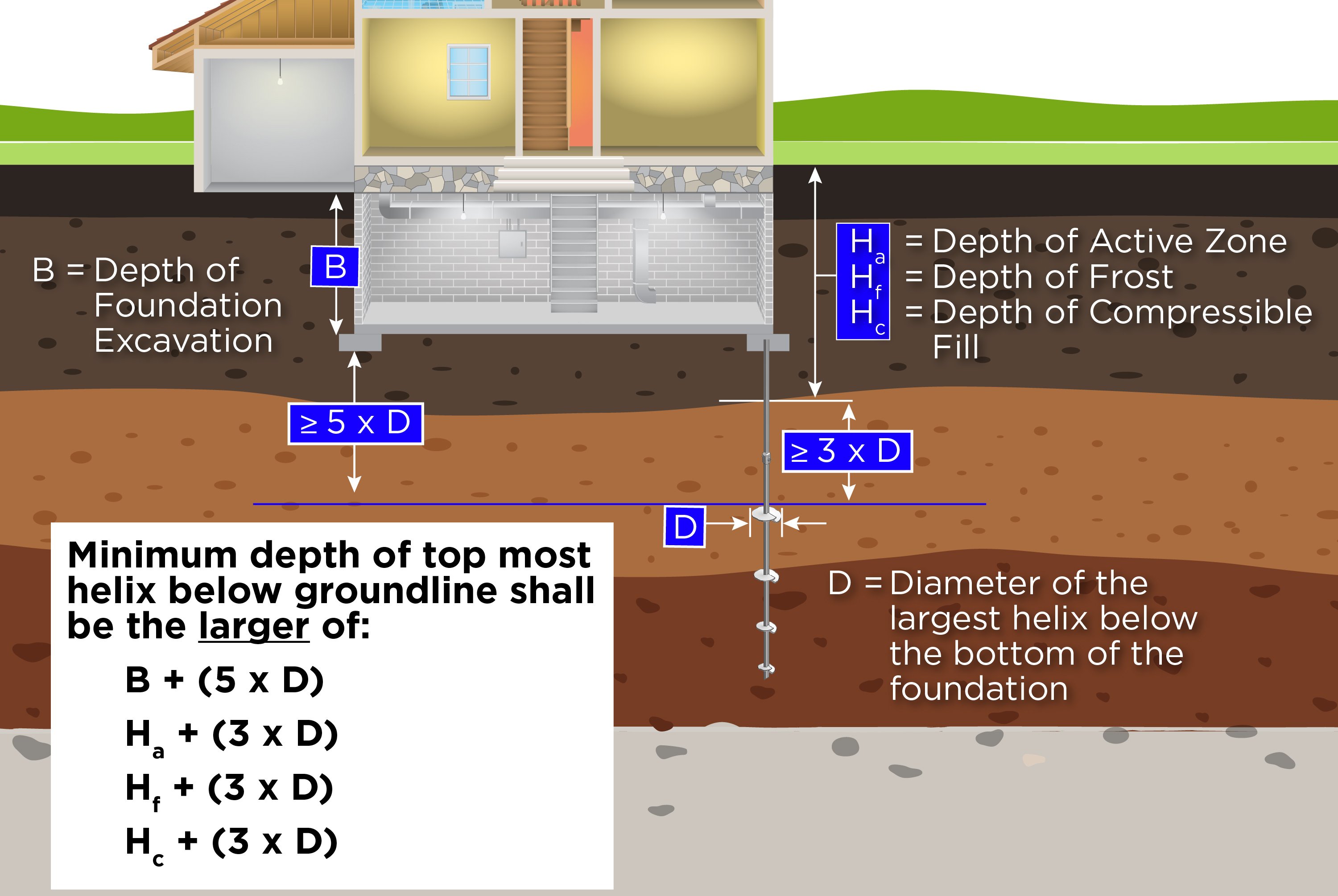

Along with a minimum torque requirement, a helical pile must be installed to a specified minimum and sometimes maximum depth. The minimum depth is recommended by CHANCE to be 5 x diameter of the largest helix below the bottom of the foundation or 3 x D below a depth of soil experiencing seasonal variations (i.e. Frost). (Section 5.2.5 – CHANCE Tech Manual). You may also have a maximum depth, if a certain soil stratum at a deeper elevation is to be avoided.

The variables of site soil conditions, required capacity, and installation torque are so intertwined that this information is all crucial when engineering a helical pile foundation design.

Question 1: Soils

Are the soils soft or firm? Are the soils clay/silt (cohesive) or sandy/gravelly (non-cohesive granular)? If the soils are gravel with cobbles, what size boulder/cobble may be expected (baseballs, basketballs, or Volkswagens)? The ability to install a helical pile into a given soil strata is very important. The pile has to get in the ground somehow, so helical pile installation is a key factor in the design stage. Dense soil stratum will typically use fewer helical plates with smaller diameters, compared to a softer clay stratum which will require more helical plates with larger diameters. Chance’s HeliCAP® v3.0 Helical Capacity Design software is a very useful tool in determining the theoretical holding capacity of a helical pile in a specific soil profile/boring.

Learn more about using HeliCAP and why it’s so beneficial for engineers.

Question 2: Loads

Loading – are we talking 10 kips, or 100 kips? A sledgehammer is not needed to hammer in an 8-penny nail. Helical piles are very similar. to the designer should select the helical pile product series that has a capacity rating greater than or equal to the load resistance required. Sometimes, a larger shaft size is needed to account for higher installation torques due to shallow layers of dense soil encountered prior to the target depth.

CHANCE Type SS Square shaft helical piles can be used in both tension and compression. Round shaft helical piles are typically used in less dense soils for compression. Some in the pile industry will say they “square shaft is only good to use in tension.” This is not true. Square shaft helical piles have been used and successfully load tested in both compression and tension. IBC section 1810.2.1 discusses lateral support of piles. “Any soil other than fluid soils shall be deemed to afford sufficient lateral support to prevent buckling of deep foundation elements… where deep foundation elements stand unbraced in air, water or fluid soils, it shall be permitted to consider them laterally supported at a point 5 feet into stiff soil or 10 feet into soft soils….” AC358 (Acceptance Criteria for Helical Systems and Devices – used to evaluate helical piles for compliance with the International Building Code® (IBC) in the form of a building code evaluation report – ESR 2794) section 3.11.2.1 defines the fluid soils as soils with SPT Blow counts of 0 (weight of hammer), soft soils with SPT blow counts greater than 0, and less than 5, firm soils with SPT blow counts equal to or greater than 5.

Watch a brief overview of structural loads

Watch a brief overview of structural loads

The loading and the soils are two very important factors to consider in selecting the proper helical pile. As an engineer, you want to provide your client with an economical solution to the problem, while considering strength and serviceability requirements. If you need engineering support, there is a local authorized CHANCE distributor in your area who has engineering experience and understanding of soil conditions in your area. Contact them today for assistance with your next helical foundation design project.

Ian Romain, P.E. is the Chief Marketing Engineer for Rocky Mountain Steel Foundations, the CHANCE Distributor for Montana, Idaho, Washington, and Northern Utah. Connect with him on LinkedIn.