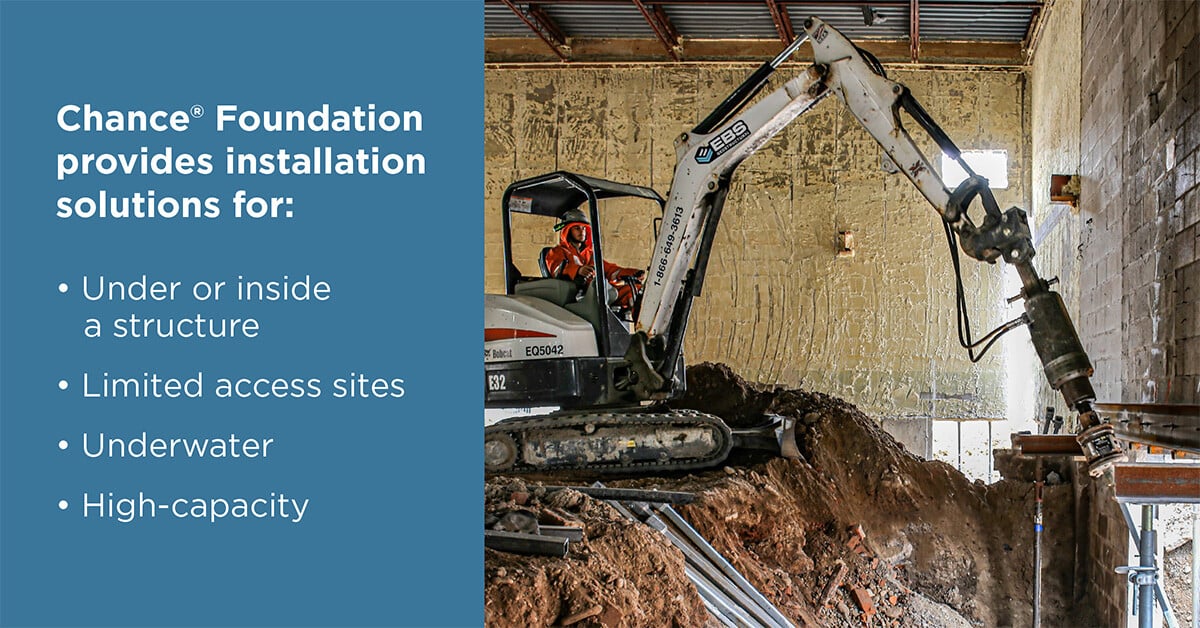

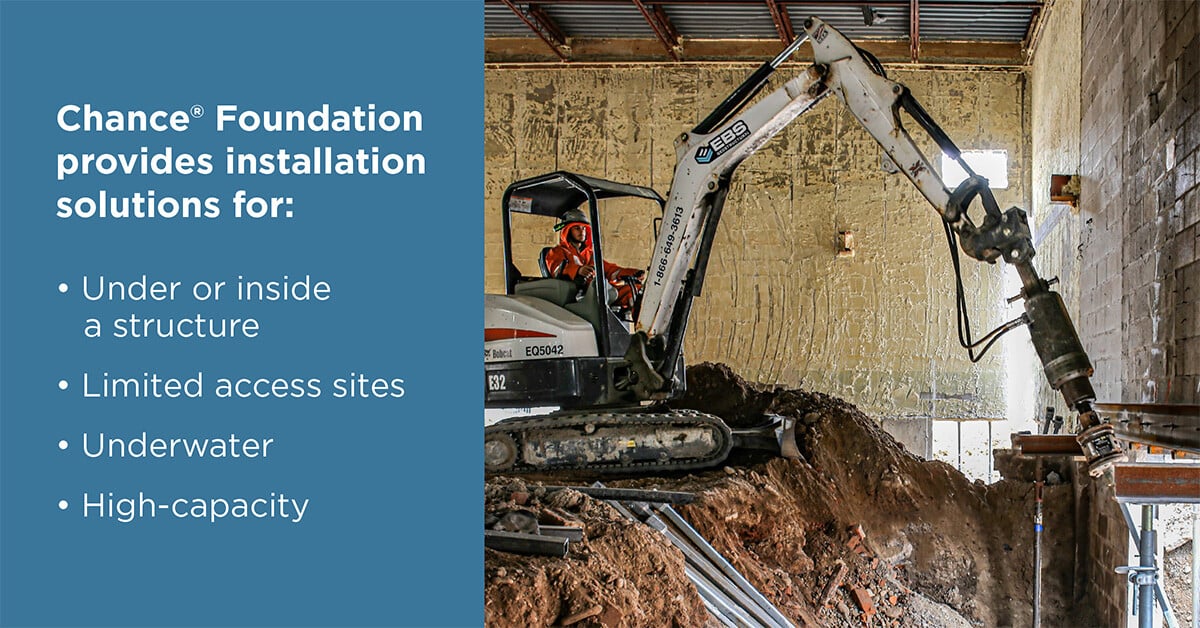

One of the clear advantages to helical piles is their size. Anyone familiar with the technology understands what that means, particularly in relation to jobsites with limitations on space. Since they can be installed with small, portable equipment, they are more versatile when you need a unique foundation solution:

There are lots of foundation solutions, but helical piles go where other deep foundations can’t. Whether installation needs to happen under or inside a structure, in a limited access site, or underwater, there is a way. Here are some examples of CHANCE helical piles providing an engineered foundation that offered predictable capacity:

Limited Access Installations with Helical Piles

Limited Access Installations with Helical Piles

Meaford Library was built on poor soil over the charred remains of a hotel destroyed by fire. When the time came to update the building, a new foundation was required. CHANCE distributor EBS Geostructural engineered plans for the foundation utilizing helical piles. They were installed indoors, and from the sidewalk outdoors; both using a Bobcat E32 compact excavator. Read more and see pictures from the jobsite.

Another excellent example is the RumFish Grill in St. Pete Beach, Florida, whose owners wanted their atrium converted to a fish tank. Working in the limited access, low headroom site and avoiding the existing water lines, helical piles were used to provide the 117 tons of capacity needed. The drilling rig was lifted over the kitchen with a crane to do the installation! Read more and watch the video.

Underwater Anchoring and Foundations

Helical piles have been installed and tested in underwater applications since the beginning of modern-day helical pile usage. Originally designed as foundations for lighthouses and piers, engineers in the 1800s realized the value of a steel deep foundation for structures in and around water. Today, helical piles are used in aqua farming, for marine tiebacks, and in pipelines, to name a few applications. Learn more about using helical piles in these challenging installation situations.

Inaccessible Jobsite

On this hurricane remediation project, access to the home could only be gained by water. The mini-excavator was brought in via boat to complete the job. Since any vibration from equipment or installation of piling could have further eroded the foundation, CHANCE helical piles were an ideal solution.

Now for the big stuff!

If you need high capacity, we can do that too. Our high capacity piles are designed with the help of modern technology and material science to support heavy-loaded structures.

Another thing that’s BIG about CHANCE Foundation Solutions is our installer network. With distributors covering the United States and Canada and Certified Installers in every state, province, and in many countries around the world, you can always find local experts with product ready to ship and knowledge ready to share. Here are some more project examples from our team showcasing the big possibilities with CHANCE helical piles:

High Capacity New Construction

“Many engineers have the idea that helical piles should only be used for residences or anything where the loads are light,” Brian Huber, Project Manager for EBS Geostructural said. “Some engineers won’t even give them a second look due to the stigma that they’re small – like putting a toothpick in the ground and expecting it to hold up a bridge.” Huber and his team engineered a new foundation for a 32-story apartment tower in London, Ontario, which, at least for now, is North America’s tallest building on helical piles. You don’t even need huge pipe to yield high capacity results – this design used 2-1/2” square shaft solid steel piles. We expect engineers will push helical pile technology to go even bigger! Read this case study.

High Capacity + Limited Access = Helical Piles

Dry Tortugas National Park is an island accessible by boat or seaplane. A 7-foot-wide bridge leads to the entry portal of the island’s historic fort. The load requirement for the new foundation construction was 30 tons of ultimate compression and 10 tons ultimate tension. Possible? Yes, with CHANCE helical piles! Learn more.

Big or Small? The Key is the RIGHT Size!

Helical piles come in a wide variety of sizes so you can right-size your project – not over or under design the foundation. We provide free helical capacity design software to ensure that engineers get the correct size and number of piles for each design. With the ability to calculate capacity, confirm it with torque monitoring during installation, and verify it with load test data, helical piles provide a clear advantage over some more traditional deep foundation methods.

If you have any questions about helical pile engineering, email our engineering team or get in touch with the engineers at your local distributor.