Often, larger commercial projects will have load test requirements included in the specifications. The number of required test piles is provided by the Engineer of Record. The number of required tests is defined as either a finite number (you must test 1 pile), or a percentage (you must test 10% of the production piles). For commercial projects, the load tests are generally included in the bid and are used to verify that the pile performs within the required deflection criteria for the required loading on the pile.

There is different acceptable criterion for load test performance (Davisson Offset, Brinch-Hansen 90%, Butler-Hoy, etc.). Typical total deflections are in the ½” to ¾” range at design load. Pre-production test piles are typically tested to 200% of design load, while production/proof tests are typically tested to 133% or 160% of design load. During the load test, you want data that shows the performance of the pile beyond 100% of the design load (which is what the pile is required to carry for serviceability).

Do I always need a load test?

Answer: Full scale load testing may not be performed on a smaller project with only a few piles; or on residential underpinning projects where the cost of a full-scale load test is prohibitive. In this case, the well-documented torque correlation values, provided by the International Building Code (IBC) are used. When lifting a structure, the piles and brackets will be tested when structure is lifted using hydraulic jacks, thus acting as a verification test.

What types of load tests are there for helical piles?

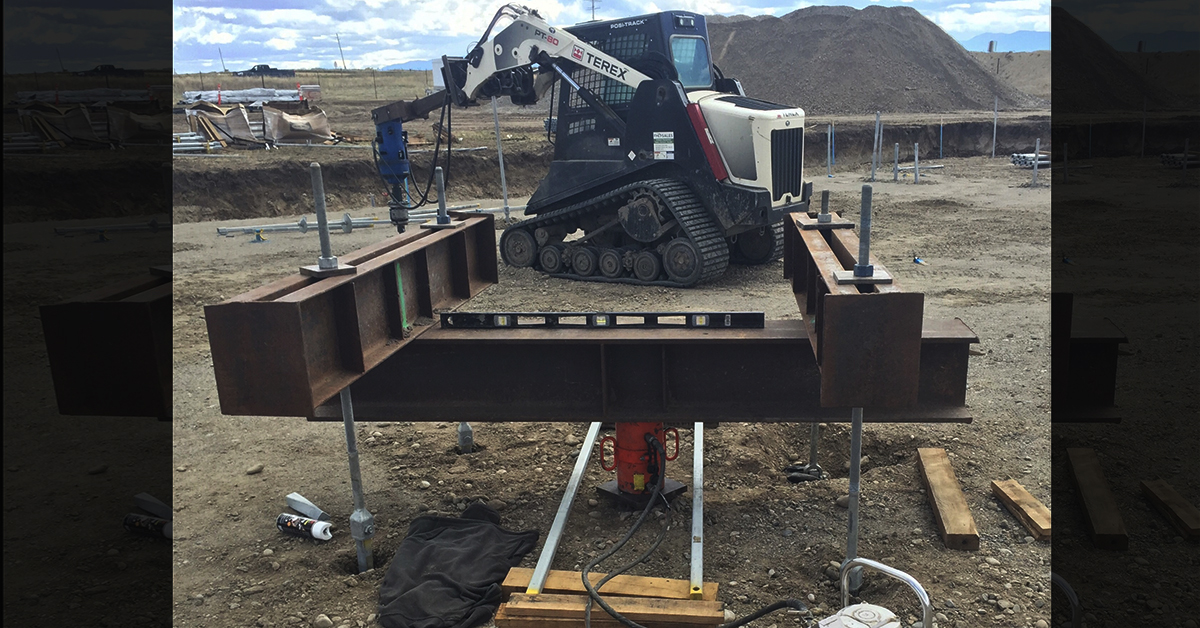

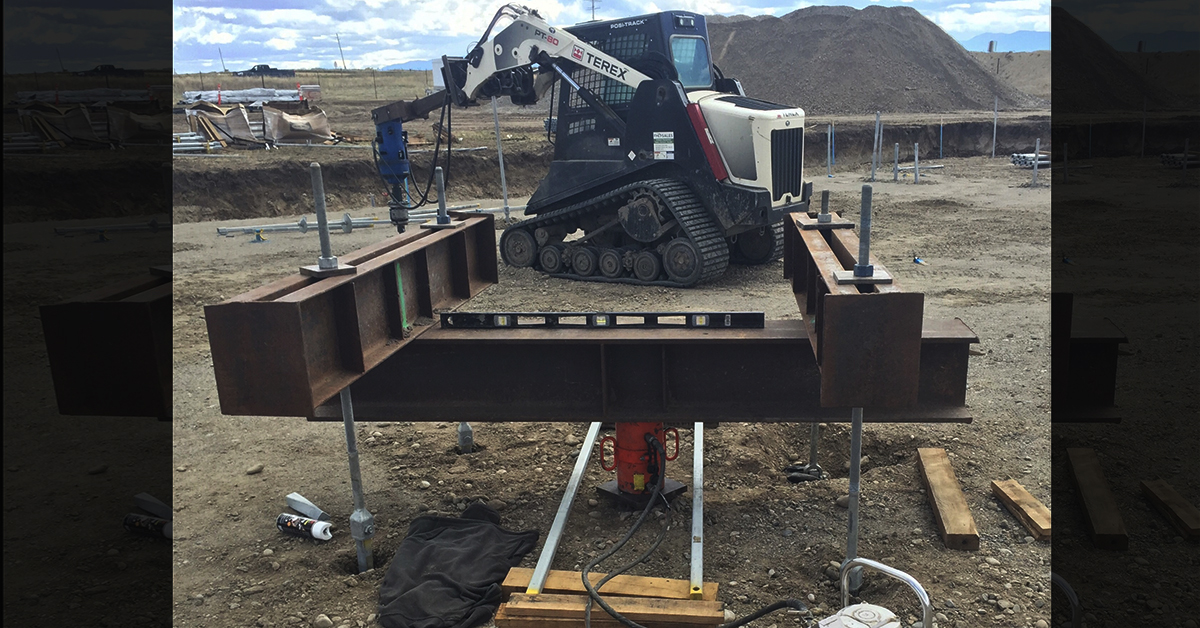

Answer: Piles can either be tested in compression (typically with a steel reaction frame and reaction piles) or in tension (typically with a load beam and wood cribbing). A full-scale compression load test is more involved and takes more time to set-up and perform. The ASTM Standard for compression load testing is ASTM D1143, and the ASTM standard for tension testing is ASTM D3689.

Section 1810.3.3.1.9 of the International Building Code (IBC) discusses the design values of helical piles, including load tests.

If Helical piles have a predictable torque-to-capacity formula, why are load tests required?

Answer: Depending on the number of piles on the project and the application, load tests are performed to confirm the torque-to-capacity relationship. Often, full-scale load tests are required on larger projects. The full-scale load test provides site specific torque-to-capacity relationship. When the project schedule allows, this data can be used to justify higher capacity of the piles, reducing the total number, and providing a more efficient design.

Are there advantages with helical piles if one underperforms during the load test?

Answer: There is a definite advantage to using helical piles for deep foundations vs. other products. During installation of the pile, torque is monitored in real time. The monitoring of torque gives the installer information about the actual soil conditions. As the torque increases, it is a clear indication that the soil strength (where the helices are located) is increasing. If a pile settles more than is acceptable during the load test, it can either be re-installed, or the capacity of the pile de-rated and additional piles added.

Is it common for a pile to “fail” its load test? If so, what would some reasons be?

Answer: It is rare that the pile will have a dramatic “failure” during the load test, provided the pile is installed per CHANCE® recommendations and tested within the range of its mechanical rating (See the CHANCE Technical Design Manual). The pile could settle or deflect beyond the acceptable limit provided by the Engineer of Record, but it has been my personal experience that the well-documented torque-to-capacity relationships hold true.

For additional information regarding load tests, and the torque to capacity relationships, contact your local distributor.