Authored by W.J. Fisher, Chairman of the Streetlight Committee at Dayton Power and Light Company in Ohio, the crew found Chance Instant Foundations to be easy to install, saving time and money.

Chance Streetlight Foundations Solve Several Problems in Streetlight Installations

Chance Streetlight Foundations Solve Several Problems in Streetlight Installations

by W.J. Fisher

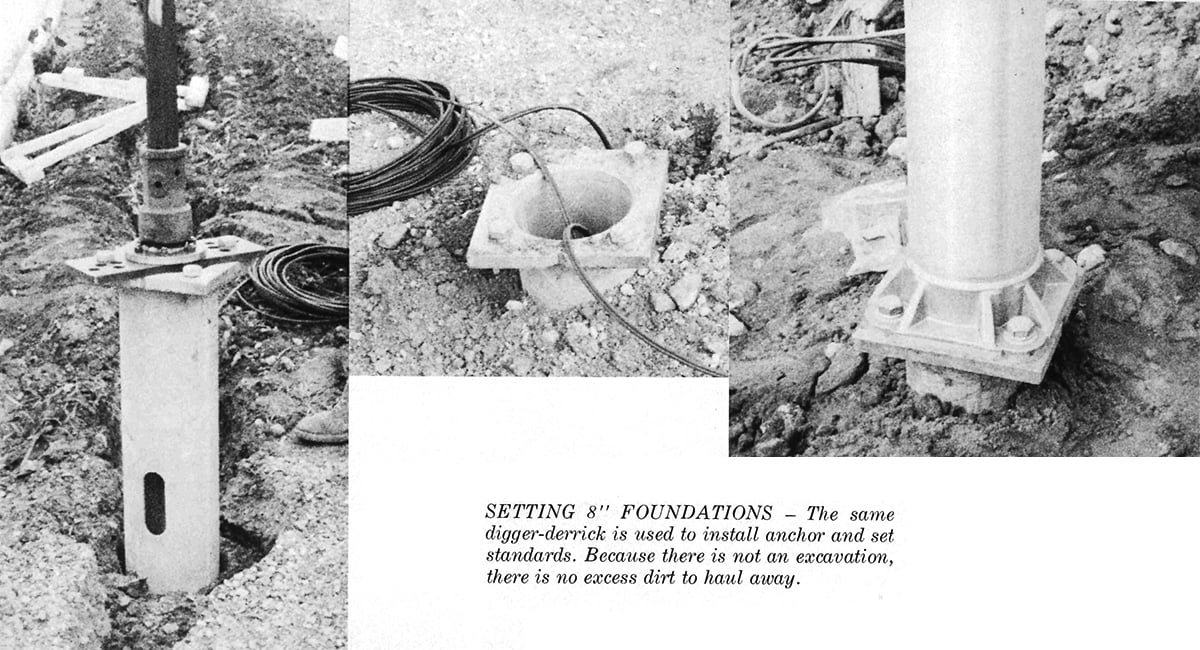

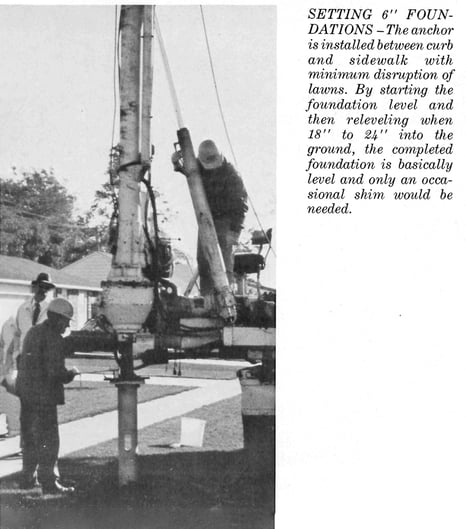

As an experimental project, Dayton Power and Light used screw-type streetlight foundations in two types of lighting projects. Chance 8” diameter foundations were used for 30'6" aluminum poles installed along a relocated four lane major connector road. Six-inch diameter foundation anchors were installed in a residential plat to support 23' aluminum poles.

The 8” diameter anchors were our first installations. Considerable experimentation was required to determine the proper equipment and procedures for this new process. After the field crew solved these operating problems, they were averaging 17 minutes to move from one site to the next, setting up the adapter plate and foundation, drilling the foundation to ground level and removing the adapter plate.

The 6” diameter anchors installed even faster. It took the crew a day and one-half (12 hours working time) to install 16 foundations. This crew had no previous experience or training on installing this foundation concept… with experience, the sixteen foundations would have taken less than one day (8 hours).

All parties concerned were very pleased and excited about the potential of the foundation anchors. The supervisors and men who install them have more reasons why they want them than we have time and pages to record. Some of these reasons are as follows:

-

No waiting for concrete trucks - when digger trucks are assigned to prepare foundations for concrete, we frequently have to have the crew standby on the location, waiting for delivery of the concrete. This new system permits “full-employment” of the digger truck and its crew.

-

No waiting for concrete to set - once the foundation anchor is installed, it is ready immediately for setting the lighting pole and completion of the project.

-

No minimum order for concrete - when only a single streetlight pole has to be installed, 1/3 (one-third) cubic yards of concrete are used, but payment is required for 3 cubic yards. This either results in an overly expensive installation or single pole installations are delayed until a group of poles are needed in a specific area.

-

Setting foundation and pole in the same day with the same crew - the operating group has complete control of a street lighting project.

-

No worry about what size conduit to use - the hollow shaft anchor has slots and serves as a cable-way itself. The job can be trenched and the wire laid in the ground before or after installing the foundations, depending upon personal preference or job conditions. The pole base can be used as a connection box.

-

Use of existing equipment - the same digger-truck can be used for all portions of the job releasing the backhoe for other work.

-

Retrievable foundations - should the lighting structure require relocating at a later date, the entire foundation can be backed-out and reused.

The Standards Committee has now approved the use of these streetlight foundations and we plan to use them for one to five pole installations. Once a crew has used them, we are confident they will be used on all streetlighting jobs where soil conditions permit.

---

Today, Chance Instant Foundations are still the preferred choice for many DOTs and municipalities for installing streetlights, area lighting, EV chargers, signage, rail infrastructure and more!

Learn more: