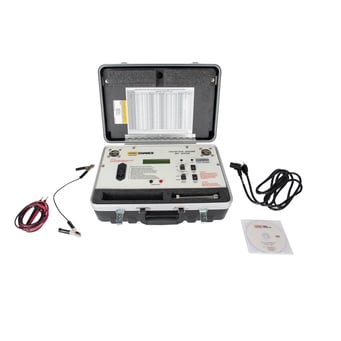

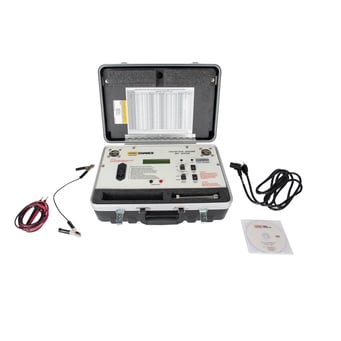

CHANCE® meters are used to detect line voltage, determine approximate phase-to-phase-voltage, check DC resistance in protective grounding sets, determine in-or-out of phase relationships, monitor leakage currents, and advise the operating condition of CHANCE hot sticks. Calibration of these meters is important in confirming their accuracy in the field and ultimately in helping to protect line personnel.

Incorrect meter readings could result in undetected or misread voltages that could be harmful to equipment and personnel.

To help avoid these issues, tool calibration should be completed whenever the user questions the accuracy of the meter. At a minimum, follow utility work procedures and OSHA/Government Regulatory rules and always follow your company’s best practices for tool calibration.

Industry Regulations:

Industry regulations for insulated hot sticks include IEEE Standard 978-1984 and OSHA Standard 1910.269(j)(2)(iii), which states:

“Live-line tools used for primary employee protection shall be removed from service every 2 years and whenever required under paragraph (j)(2)(ii) of this section for examination, cleaning, repair and testing...”

These standards apply directly to insulated, live-line tool (Hot Sticks) not specifically to the attached Meter. We do recommend that each meter be wiped clean and visually inspected for defects before use each day. Field test methods are outlined in the meter’s operation & maintenance guide (available online by: navigating to the Instruments & Meters page on the website, choosing any of the HLT “Hot Line Tool” Meters listed, selecting the specific product of interest by clicking VIEW DETAILS, then clicking RESOURCES/DOWNLOADS).

If any defect or contamination that could adversely affect the proper operation, accuracy or mechanical integrity of the tool is suspected, the meter shall be removed from service. Before placing back into service, the meter should be properly inspected, repaired & tested for full operation.

Please see below for additional inspection and repair directions.

For Calibration and/or Repair, please send the unit to:

BEVINS CO.

ATTN: REPAIRS

9903 E 54th St

Tulsa, OK 74146

Please include name, phone number and address of contact inside the box and attention repairs outside the box. A short description of the problem should also be included inside the returned unit.

Contact for Repairs and Calibration: Bevins Co. at 918-627-1273 or support@bevinsco.com

Bevins Co can provide an estimate before they start the repair. Once they have received approval for the repairs, the repairs will then be completed, and the tools will be returned to you. Standard turnaround is 2-3 weeks after receiving the tool, unless major repairs are required. If no parts require replacement, it is normally $85 to test, clean, and calibrate Hotline tools. Customers are required to pay with a credit card until credit has been established.

Bevins Co. repairs Hubbell® / A.B. Chance® brand Hot Stick Testers, Ground Set Testers, High Voltage Testers, Phasing Sticks, Capstan Hoists, Strap Hoists, and Wireless Torque Indicators. Bevins Company products are sold through Hubbell Power Systems. Contact your Hubbell representative for new Tool pricing.