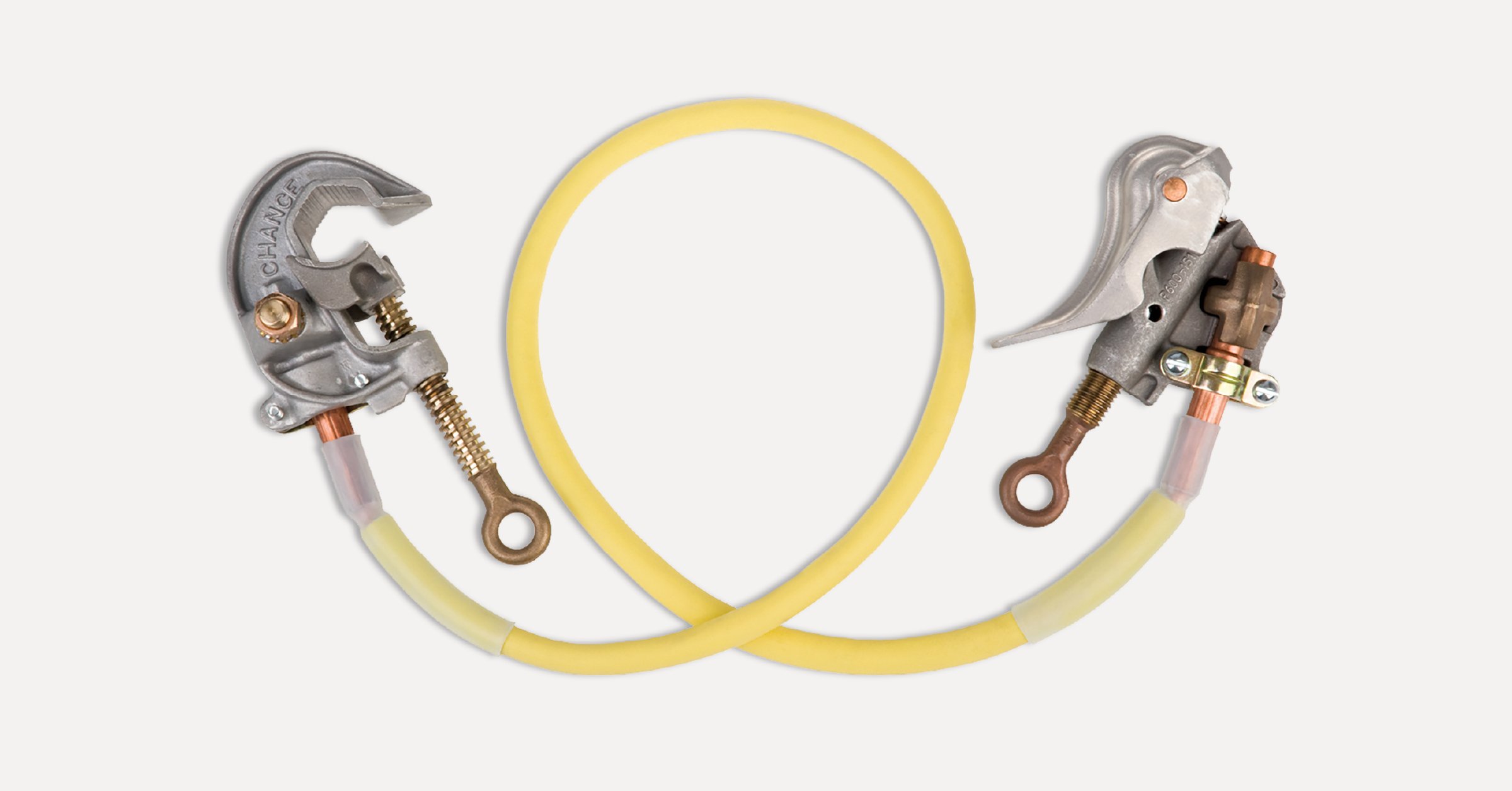

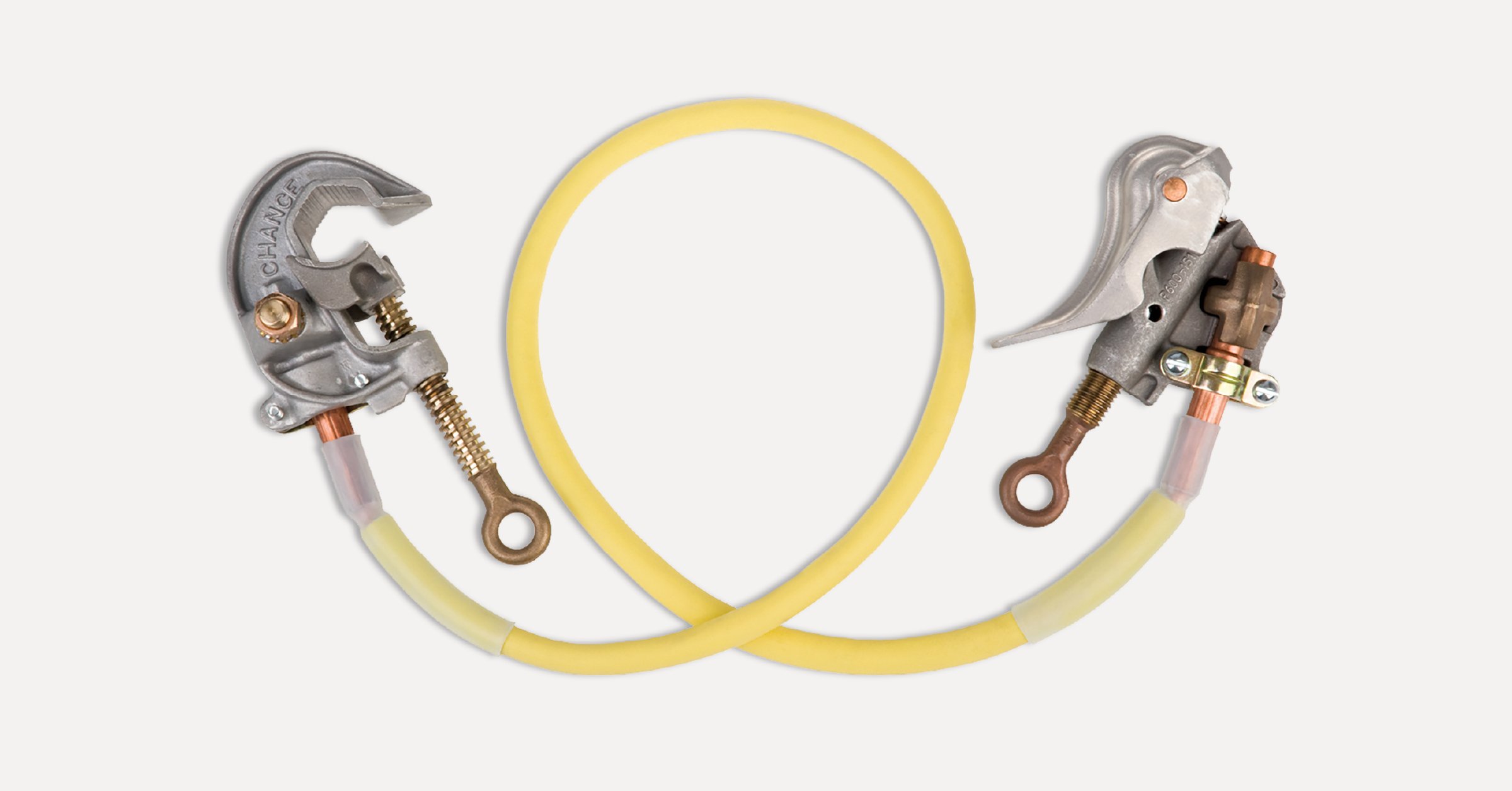

Every day, linemen around the world rely on temporary protective grounding sets to protect them while performing de-energized and grounded line maintenance. These temporary protective grounding sets are designed to handle a large amount of fault current in a very short period, which can typically range from a quarter to half a second (15 to 30 cycles on 60 hz systems).

The purposes of temporary grounding sets

It is critical that temporary grounding sets are properly assembled using components rated and tested to the ASTM F855 standard. OSHA 1910.269 also references the F855 standard in paragraph 1910.269(n)(4). The temporary grounding sets serve three purposes per 1910.269:

- 1. 1910.269(n)(3) Equipotential zone. Temporary protective grounds shall be placed at such locations and arranged in such a manner that the employer can demonstrate will prevent each employee from being exposed to hazardous differences in electric potential.

-

- 2. 1910.269(n)(4)(i) Protective grounding equipment shall be capable of conducting the maximum fault current that could flow at the point of grounding for the time necessary to clear the fault.

-

- 3. 1910.269(n)(4)(iii) Protective grounds shall have an impedance low enough so that they do not delay the operation of protective devices in case of accidental energizing of the lines or equipment.

-

A fault is typically a very violent, loud, and fast event. Properly rated, tested, assembled, inspected, and installed temporary protective grounding will help ensure linemen stay safe while performing de-energized maintenance.

Dangers of untested grounding cables

All components of a temporary grounding set are important and should be carefully selected. On the topic of grounding cable, there are several reasons why untested cable should not be used:

- 1. Proper Testing:

- Standard off-the-shelf cable, such as welding cable, may not be able to handle your systems’ maximum fault current. The cable needs to be design tested per ASTM F855 to ensure it will handle the maximum fault current without fusing or breaking from the electrical and mechanical forces. If the cable were to fail, there would be no protection, and could result in severe injury or death.

2. Proper Crimping: - Factory recommendations for crimping ferrules to temporary grounding cable have been precisely formulated to ensure the crimped ferrule can survive the electrical and mechanical forces during a fault current. Standard off-the-shelf cable could have different dimensions, such as the diameter of the stranded cable, relative to the cable used by the manufacturer of the ferrules. These variances, without proper fault current design testing, could result in the temporary ground set failing during a fault. This may lead to severe injury or death.

3. Proper Material:- ASTM F855 section 35 requires the temporary grounding cable to be a copper conductor, stranding to be Class K or M, and to meet the DC resistance requirements of ASTM B172. The jacket thickness is required to be a minimum of 1.14mm (0.045 in.). Off-the-shelf cable may not meet these requirements and may not provide adequate protection.

-

Temporary protective grounding training

Proper temporary protective grounding requires specific knowledge and training. An excellent resource is the Chance Encyclopedia of Grounding. For questions on temporary protective grounding or to schedule training with a Chance expert, please reach out to your local Hubbell Power Systems Territory Manager or fill out this form.