The performance of utility brackets is critical, especially in the event of a major storm or natural disaster where you need maximum support for expensive equipment. So how do you decide on aluminum versus steel brackets to support your equipment? Here are five quick ways that aluminum outperforms steel every time when used to make utility brackets.

- Aluminum material is known for its durability

in neutral and slightly acidic environments. This makes Hubbell aluminum brackets out-perform steel brackets in corrosive environments.

in neutral and slightly acidic environments. This makes Hubbell aluminum brackets out-perform steel brackets in corrosive environments.

- Aluminum products are fabricated and assembled from engineered cross sectional aluminum shapes.

- The material has a high strength to weight ratio which allows it to support heavy equipment.

- Aluminum brackets weigh significantly less than the equivalent steel product.

- Products are easier to handle for line crews and warehouse personnel.

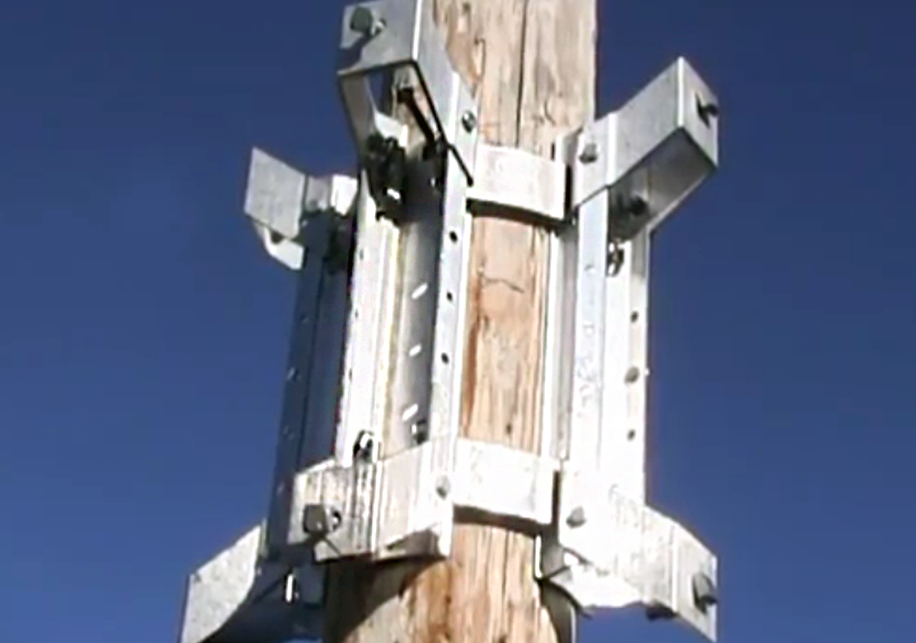

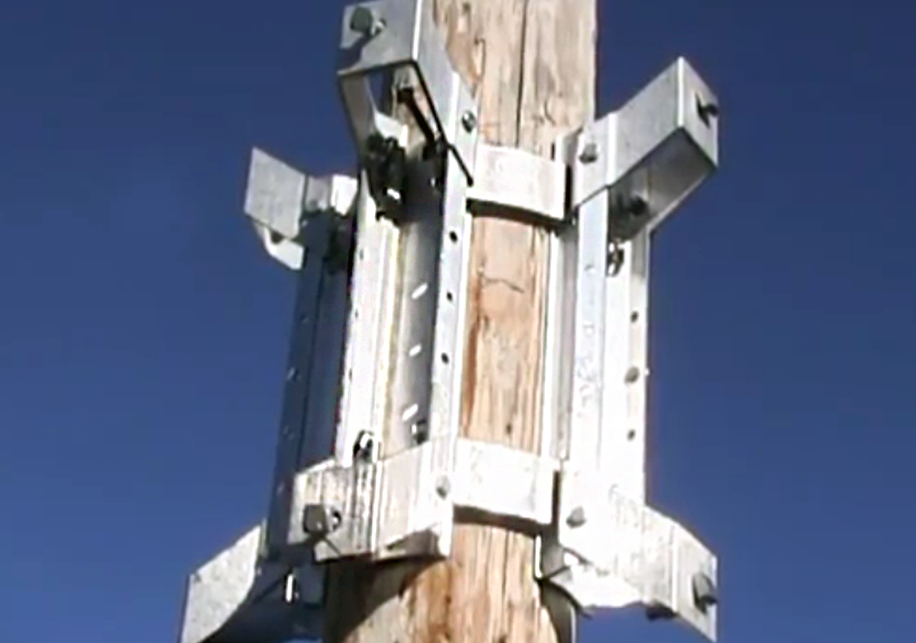

Aluminum brackets can support virtually every type of pole mounted equipment for a utility, including cutouts, arresters, cable terminators, reclosers, single phase switches, transformers, capacitors, primary metering and regulators. They can also support conduits in riser applications. Aluminum brackets have been engineered to satisfy the industry needs for these applications.