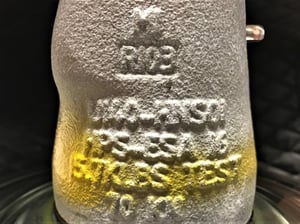

Toughened glass bell insulators are easily identified through the application of color bands on the caps, signifying the most common strength class products.

Standards

Currently there are no formal standards found in either ANSI or CSA specifications that outline or require the presence of these color bands. Over their years of use, these color bands have been introduced into existence by individual consumers of toughened glass bell insulators. Some have made the use of color bands a requirement by incorporating them into their individual standards, therefore expanding their growth and commonality in the field. Typically the designations are as follows:

- Yellow Band – 30k lbs. / 140 kN – ANSI Class 52-5H

- Blue Band – 40k lbs. / 180 kN – ANSI Class 52-8H

- Red Band – 50k lbs. / 222 kN – ANSI Class 52-11 – CSA Type CS-11

Benefit

The primary benefit of using the color band designation is ease of identification. However, there are numerous application purposes to the color banding system.

- There is the process of inspection. When the material arrives, the color banding allows material handling associates to quickly identify product and ensure labeling is correct. This can also help if product is relabeled before it moves out of a storage location and into the field for installation. Linemen can recognize similar color banding and minimize the risk of improper strengths being used for a particular application.

- There is the benefit of identification from a distance once the structures are in place. This is not only helpful during the inspection phase immediately following construction, but for future inspections if any issues arise or individual bells need to be replaced during normal maintenance. This distance allows employees to remain safely on the ground to identify the proper strength rating.

Without the color bands, employees would need to get close enough to identify the makings forged and printed onto the cap of the toughened glass bell during manufacturing.