All Hubbell Power Systems surge arresters are factory tested according to IEEE C62.11 and IEC 60099-4 routine test requirements. Once in use, surge arresters do not require field testing for routine maintenance. If arrester field testing is desired there are several test options with varying levels of usefulness and convenience.

It is important to note that there is not a single field test that assess the comprehensive operating characteristics of an arrester.

Test method while the arrester is in service.

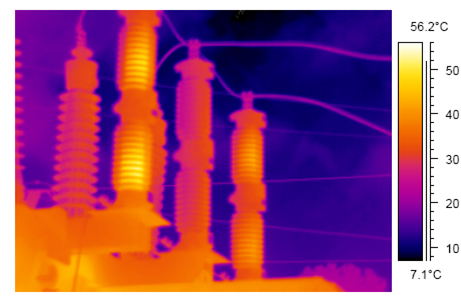

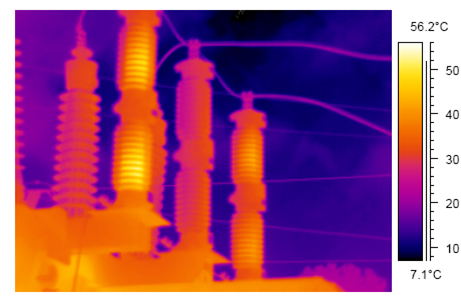

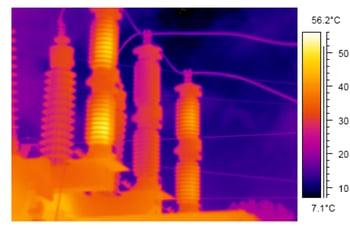

Infrared imaging is the simplest and most efficient field inspection test if done on a periodic basis. Infrared imaging compares arresters, that are similar in age and history, for significant differences. During this test, arresters are not taken out of service.

Therefore, Hubbell Power Systems recommends monitoring the temperature of the arresters in accordance with the NEETRAC Project 10-53 guidelines provided below:

- Less than or equal to 11°C higher than a close reference – no action

- Greater than 11°C but less than or equal to 22°C – increased surveillance

- Greater than 22°C higher than ambient – remove and replace arrester in a timely manner.

These guidelines should also be used to monitor the temperature of installed arresters.

Test methods while the arrester is not in service.

To perform IEEE C62.11 and IEC 60099-4 tests, the arresters must be transported to a high voltage laboratory. These tests will identify discharge/residual voltage, reference voltage, partial discharge and watts loss. To further assess an arrester’s condition, include measurement of the resistive component of current and third harmonic leakage current. Baseline measurements from the manufacturer are necessary to compare against present time measurements.

Another common test being performed is measuring total leakage current (or power loss) at a voltage of 5 or 10 kV. The arrester’s aging components will manifest as high resistive current at voltages close to the turn on voltage of the arrester. However, because most arresters have a turn on voltage greater than 10 kV, the use of total current measurements at lower voltage does not provide a good diagnosis of the health of the surge arrester. Therefore, Hubbell Power Systems does not endorse testing surge arresters at low voltages because the resultant test values are not indicative of arrester health.

Join our upcoming webinar to learn more about additional considerations for surge arrester field testing.