Anchors have been used by utilities since 1912. It was then that a young Albert Bishop Chance (age 33) invented and later patented an anchor to restore and secure telephone poles that had fallen in an ice storm in his hometown of Centralia, Missouri. CHANCE Anchors are still made in Centralia today, along with other key components and tools engineered and manufactured to provide the best installation experience for CHANCE helical anchors.

There are many kinds of anchors used by utilities in different conditions and for different applications – rock anchors, expanding anchors, cross-plate anchors, and more. Certain tools may be used for different types of applications, but this article will focus specifically on CHANCE® PISA Anchors. The acronym PISA stands for Power Installed Screw Anchor and describes the family of CHANCE anchors that are installed using the digger motor on trucks to screw the anchor into the ground.

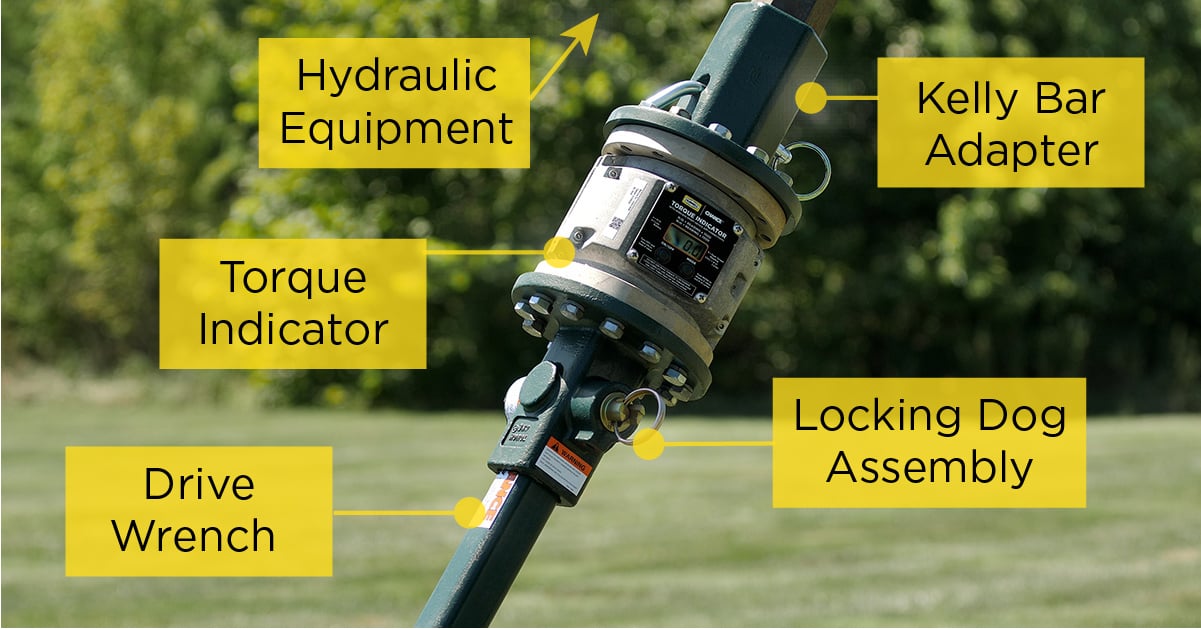

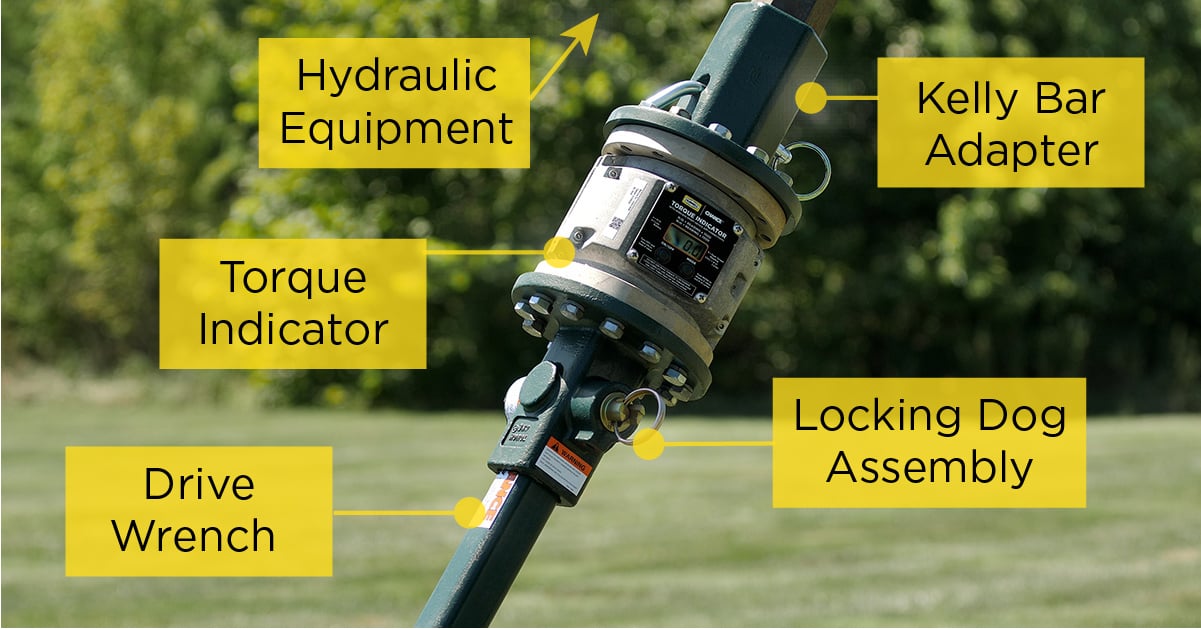

5 components that workers use for a successful helical anchor installation are:

1. Hydraulic Equipment

PISA anchors are installed using construction equipment that can utilize a torque motor and Kelly bar, most commonly a digger derrick. In hard-to-access sites, installers may use a compact “backyard” derrick.

2. Kelly Bar Adapter

The Kelly bar adapter is a steel casting socket that attaches directly to a truck’s torque motor’s drive shaft (Kelly bar) and locks in place with a bent arm pin and coil lock.

3. Torque Indicator

An optional tool, but very useful, is the torque indicator. With variable bolt hole circles, it can be mounted between any CHANCE Kelly Bar Adapter and Locking Dog Assembly. The amount of rotational force put out by the digger motor is measured in foot-pounds of torque. Torque is important when installing anchors because the harder the soils, the higher the torque required. The A.B. Chance Company Engineers have researched and tested the correlation between torque and anchor holding capacity for decades. By measuring torque during installation, you can be confident of an anchor’s capacity. Bonus – the new CHANCE digital torque indicator sends those readings directly to your phone where they can be saved or shared!

4. Locking Dog Assembly

A crucial link, the Locking Dog Assembly connects the Kelly bar adapter (or torque indicator) to the drive wrench. The spring-loaded locking dogs easily snap into place to hold the drive wrench and forged hex on the anchor rod. To ensure the anchor and tool are firmly connected we recommend always giving the anchor a tug before starting installation – just to double check.

5. Drive Wrench

This square hollow bar is 7’ long to match the length of the anchor rod. The anchor rod slides inside the tube of the drive wrench and attaches to the Locking Dog Assembly. There are various size drive wrenches to fit different size anchors.

Each piece of the anchor tooling string works together to give the operator a safe and reliable package for anchor installation. Tools can be selected in standard (10,000 ft-lb of torque) and a TOUGH ONE® (up to 15,000 ft-lb of torque) configurations, to ensure you have the right-sized tools for the job. Learn how to match CHANCE Anchors with the correct installing wrenches.

Get the complete Product Feature and Selection Guide for CHANCE Anchor Tools.

Access part numbers and detailed descriptions in the CHANCE Anchor Tools Catalog.