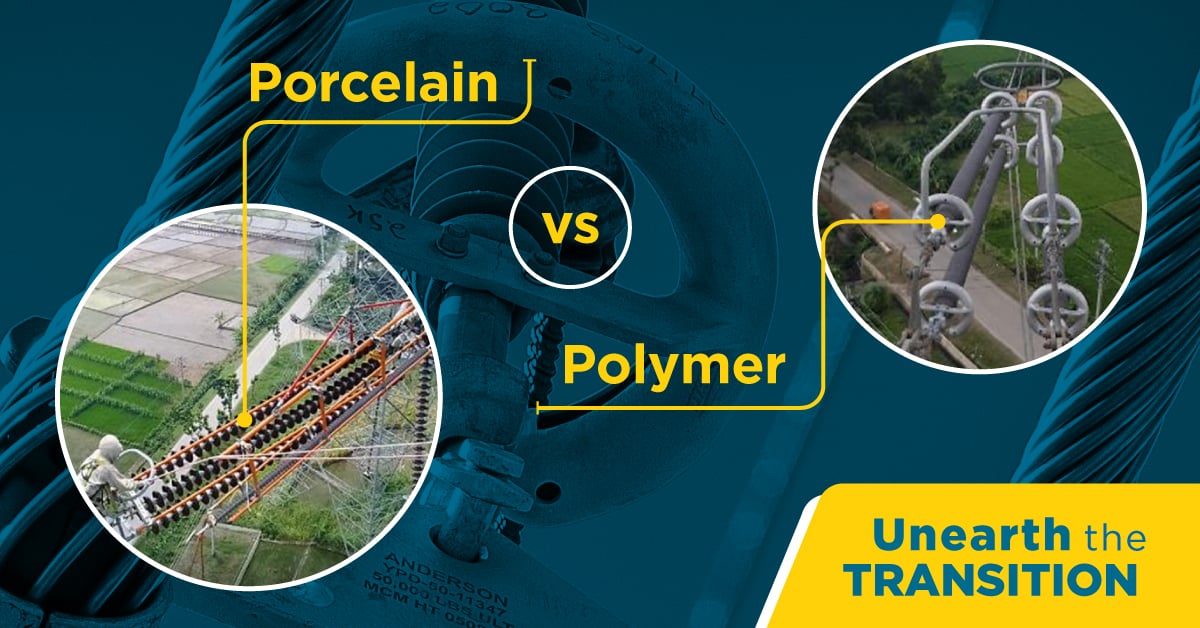

Looking at polymer insulators, we’ve considered several factors that determine superior material and product performance. But then you ultimately need to ask, how do you begin to replace porcelain strings with polymer insulators?

To do that, we need to consider equivalence. This is how we set criteria that allows us to determine what characteristics are critical for switching to polymer.

This brief overview covers the insulator characteristics you need to consider when finding a suitable polymer equivalent to porcelain string. For an in-depth discussion, please read the detailed white paper.

Physical and Electrical Characteristics

There are two broad categories of functional performance equivalence to look at, the physical and electrical characteristics.

Physical equivalence has two aspects. These are defining the mechanical strength of the porcelain bells and determining the appropriate section length. Polymer insulator designs offer various strength ratings as well as the ability to effectively match the section length. This minimizes the impact to existing porcelain bell string designs.

Then the electrical characteristics must be analyzed for suitability with the system voltage. The three types of stress typically considered are:

- 60 Hz power frequency

- switching impulse

- lightning impulse voltage

Therefore, the electrical characteristics must be verified after selecting the right strength and size insulator.

Beyond other electrical stresses, transmission line flashovers at nominal system voltage are often caused by contamination build-up on the insulator string. Therefore, comparing leakage distances of insulators is important for determining performance under these conditions.

Making the Comparison

The ultimate strength of porcelain suspension insulators is characterized by the porcelain mechanical and electrical (M & E) value. For polymer suspension insulators, the equivalent measure is the specified mechanical load (SML).

To select a proper strength Hubbell polymer insulator, choose one with an SML equal to or greater than the M & E value of the porcelain insulator. From there, an understanding of the required electrical ratings of the line leads to ensuring the polymer insulator meets the specific design criteria.

In many cases, the polymer insulator of similar SML will meet or exceed the required electrical ratings. Providing increased leakage distance depends on shed profile, leading to improved contamination performance over the same section length of a porcelain string.

More Considerations Switching from Porcelain to Polymer Insulators

Hubbell Quadri*Sil polymer insulators can provide effective alternatives to porcelain strings when the proper characteristics of the transmission line and assembly are taken into consideration.

But don’t just take our word for it. Check out our white paper which includes the calculations and examples. You’ll find detailed guidelines in “Polymer vs Porcelain Suspension Insulator Equivalence—What to Use?”.

We hope you enjoyed our educational series about polymer insulators. If you missed any installment, check out the entire blog series now. We’re here to help. To talk to someone, please reach out to your Hubbell sales rep.