Featured Post

Maintaining Load During a Helical Pile Compression or Tension Test

Written by Ben Jennings, P.E.

Performing a load test is the best way to confirm pile capacity. It confirms if the pile has the capacity required to support the load applied. During most tests, the load is increased in time intervals and then held at...

All Posts

Written by Jason Herron, PE, CWI

Adding grout to a helical pile shaft is a popular option for many reasons. Grout is used to:

Written by Chance Foundation Solutions

A variety of systems plus possible modifications results in a wide offering of retaining...

Written by Ian Romain, P.E.

Building a deck is like crafting the perfect outdoor sanctuary; a space where family gatherings,...

Written by Gary L. Seider, PE

Helical piles come in a variety of types and sizes, giving engineers and contractors flexibility to...

Written by Kailani Andersen-Derasmo, Project Engineer

Hanalei Weke Road is nestled between Hanalei Bay and mountains and nature preserves on the...

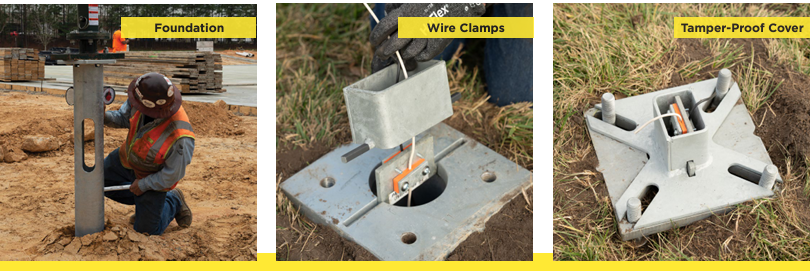

Written by Chance Foundation Solutions

From New York to Los Angeles, Edmonton to Denver, copper wire theft is an all-too-common problem...

Written by Chance Foundation Solutions

December 2024 Update - Read more about Scope 3 emissions from the Deep Foundations Institute!...

Written by Ben Jennings, P.E.

The number of Electric Vehicles (EV’s) on the road is ever increasing. As such, so are the number...

Written by Ground Sun UK

A £7.5m water treatment infrastructure project was being constructed in Staffordshire, UK. Access...

Written by Gary L. Seider, PE

Since the mid 1990’s, Hubbell Power Systems, Inc. has held an ICC-ES Evaluation Report for several...

Written by Foundation Technologies, Inc.

A large brownfield site stood three blocks from the center of Hartsville, South Carolina....

Written by Gary L. Seider, PE

When installing a helical pile foundation, the installing contractor is responsible for inspection...

Written by Chance Foundation Solutions

From "Preservation of Historic Structures Using Screw-Pile Foundations" by Dr. Alan J. Lutenegger,...