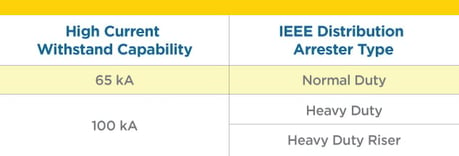

There are three distribution arrester types commonly used to protect overhead distribution equipment from the damaging effects of overvoltage. IEEE C62.11 defines Normal Duty (ND) and Heavy Duty (HD) classes by their ability to withstand certain current impulse levels. The third, Heavy Duty Riser is a type, or variation, of the HD classification and utilizes a larger diameter Metal Oxide Varistor (MOV) disc.

Distribution Arrester Protection

The simplest way to explain the difference between these three types is by comparing the protection being provided to the equipment. Since arresters protect by clamping surges to a voltage level that insulation can handle, this value should be as low as possible to reduce wear and tear on critical distribution equipment.

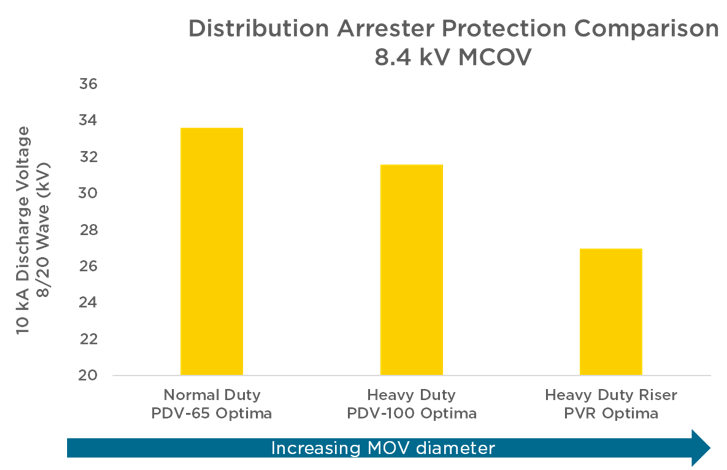

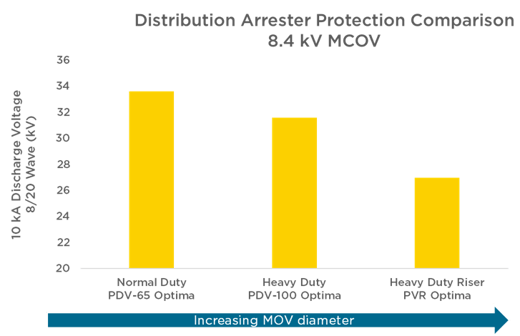

The MOV is the heart of every arrester which gives them their protective capability. The figure below shows the protection improvement or lowering of discharge voltages while the arrester MOV diameter’s increase. As the diameter of the cylindrical disc increases, more current paths become available for the arrester to effectively handle surge events.

IEEE Distribution Arrester Types

The Normal Duty arrester can be defined as a base level of protection, ideal for areas that have less lightning activity. The Heavy Duty arrester has a lower, better discharge voltage and are commonly used to protect systems exposed to severe lightning current. The Heavy Duty Riser has the best protective level of the three and is typically used to protect underground distribution cable and equipment.

Hubbell Power Systems, Inc. designs and manufactures the highest quality surge arresters for customers around the world. Our IEEE distribution arresters are 100% routine tested and designed to meet or exceed the requirements of IEEE C62.11 for Normal Duty and Heavy Duty arresters.

For more information on these distribution arrester types, contact your HPS representative.