CHANCE brand anchors installation tools are critical to the construction of overhead electric and communication infrastructure. As with most mechanical devices, CHANCE anchor installation tools require periodic maintenance checks to assure peak performance and crew safety.

Anchor Installation Tool Maintenance Tips

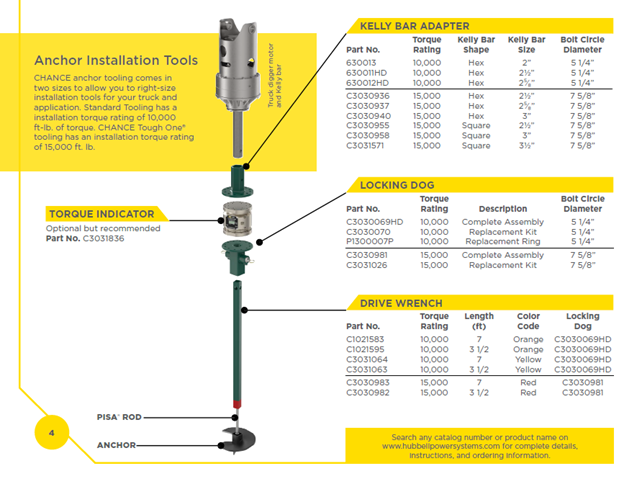

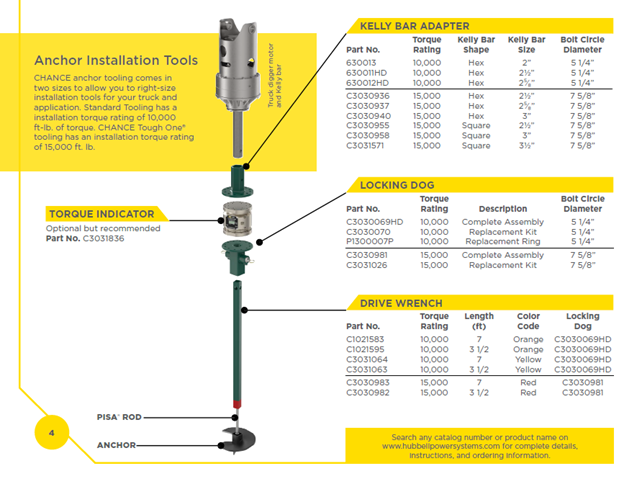

No matter their size or application, all anchor installation tools require consistent maintenance to ensure peak performance and function. Read on to discover some essential maintenance tips for anchor installation products such as the Locking Dog Assembly, Kelly Bar Adapter, and Drive Wrench.

Locking-Dog Assembly Anchor Installation Tool

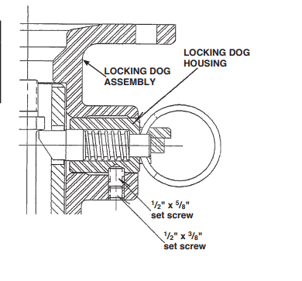

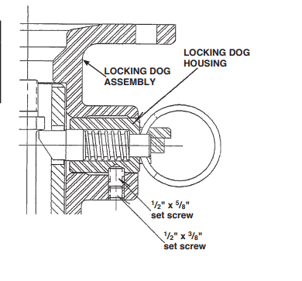

The CHANCE Locking-Dog Assembly is an anchor installation tool that requires periodic inspection. When the Locking-Dog Assembly is correctly positioned and in good working order, it ensures complete and positive capture of the anchor-installing wrench drive tube and anchor rod.

The CHANCE Locking-Dog Assembly is an anchor installation tool that requires periodic inspection. When the Locking-Dog Assembly is correctly positioned and in good working order, it ensures complete and positive capture of the anchor-installing wrench drive tube and anchor rod.

If locking dogs do not rotate smoothly or engage easily into the “in” and “out” positions, wrench and rod capture may be incorrect. If the dogs become worn or damaged due to ineffective rotation, it is best to order new ones from CHANCE. When inspecting the Locking-Dog Assembly, check to ensure the set screws are holding the two-dog assemblies are in position. There are two set screw located below each “dog.”

Kelly Bar Adapter Anchor Tool

Kelly Bar Adapters attach to the digger/torque motors square or hex shape drive shaft to install anchors or piles. All output string bolts used in the Adapter’s drive-train system should be checked for tightness. Loose or damaged bolts may fail at or below the anchor’s torque rating and contribute to damage elsewhere within the tool assembly. Lost or damaged bolts can cause failure at or below the anchor torque rating, as well as contribute to damage elsewhere on the output string.

During anchor installation, keep the anchor-drive wrench in alignment with anchor to prevent uneven wear or damage to the tool. Misalignment puts extremely high stress on the end of the wrench where the wrench fits over the anchor, which can possibly cause the drive tube to split at the end.

Drive Wrench Anchor Installation Tool

Anchor drive wrenches can fail when excess torque is applied above their rating. This excess torque most often occurs when the wrench is subjected to bending, shock loading due to rocks, or anchor breakage. CHANCE wrench tubes are designed to fail in a ductile manner. Generally, these wrench tubes will twist along their lengths under conditions of failure.

Wrench tubes can be processed to make them harder and stronger to increase their torque rating. However, limitations in wrench cross-section geometry can cause the wrench to fail in a non-ductile or brittle manner. Brittle failures are dangerous to workers because the wrench tube can fracture into pieces and fly outward from the tool string. CHANCE wrenches are processed to maintain ductility and strength in multiple scenarios, eliminating this potential danger. Over time, all wrench system components will wear due to continued use. Wear and tear are normal and should be monitored closely to establish a tool component replacement schedule.

Explore CHANCE Anchor Installation Tools

CHANCE anchor installation tools enable users to quickly install anchors in a variety of environments. To learn more about the anchor installation tools featured above, feel free to browse our complete list of anchor installation tools or check out our complete Anchor Enclyclopedia. You can also use the Chance Anchor Tool Inspection Checklist to help ensure tools are maintained properly.

The

The