There are several types of automatic circuit recloser technologies for the electric utility industry. Each technology incorporates various feature classifications: number of phases, voltage class, medium for interruption, and control mechanism type. Both Oil Circuit Reclosers (OCR) and Electronic Reclosers have been in the industry for quite some time. Each of these recloser types provides a unique benefit to the power grid but also both present certain challenges.

Challenges of OCR Reclosers:

- The OCR is a heavy product, which can make installation difficult on linemen. The recloser typically weighs between 85 to 210 lbs depending on product model and specifications.

- The technology is unable to be reprogrammed (i.e., minimum trip, time current curve options, number of operations to lockout, etc.) which requires a larger inventory. Also, the recloser operates with a factory set current rating and time current curves which reduces the customization capabilities if coordination changes need to be made.

- The OCR is an oil filled recloser which requires regular oil maintenance. Manufacturers typically recommend that utilities inspect, clean, and fill the recloser with new oil every three to six years.

- Since the OCR uses oil to operate, it is not environmentally friendly.

- The operation of OCR reclosers can vary with climate change. For example, colder temperatures can cause higher viscosity and slower recloser operation.

Challenges of Traditional Electronic Reclosers:

- Due to the grounded design, electronic reclosers are more susceptible to dielectric issues from lightning surges.

- The weight of electronic reclosers is between 100 lbs. and 150 lbs. which requires the use of a hoist and additional personnel to install.

- A separate control is required to perform recloser operations and program the recloser.

- A power transformer (PT) is required to provide power for the separate control.

- Electronic reclosers are both voltage and battery dependent.

- Traditional electronic reclosers require a PT to power the control. A failure of the PT will result in the failure of the recloser to operate under faulting conditions.

- During a fault, the control needs the battery to operate if the line voltage dips. This voltage drop can result in the AC voltage being insufficient to power the control from the AC source alone. Therefore, the control must supplement power from the battery to keep it powered and to perform reclose operations.

Understanding the Versa-Tech Recloser Technology:

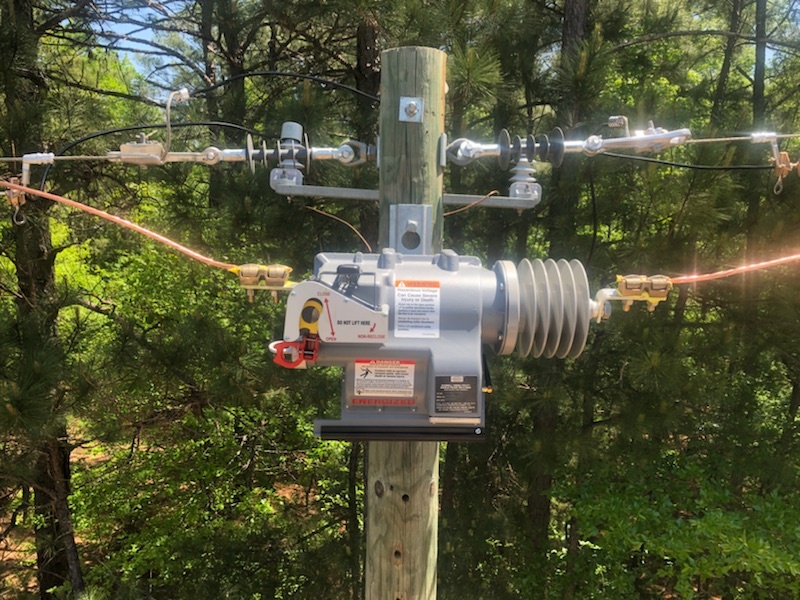

The Versa-Tech® recloser was the first single-phase electronic recloser to provide the ease of use of an OCR with advanced features of traditional electronic reclosers into one lightweight, compact design. With a footprint of 46 lbs., the Versa-Tech allows for easier handling and installation than alternative recloser options.

The Versa-Tech recloser incorporates a unique and patented approach by combining the interrupter, drive mechanism, and control into a single housing raised to the system potential. This approach enables the Versa-Tech to be line-powered, thus eliminating the need for a separately-powered control. The power for the control is harvested from both fault and load current using two power current transformers.

The system potential design eliminates the need for grounding, which reduces dielectric failures and increases lightning immunity. Additionally there is no need to purchase or install additional hardware for the unit and no battery required to perform reclose operations.

Versa-Tech Benefits:

Safety

- Self-contained vacuum interrupter allows for both fault and load breaking and making capability.

- Hot Line Trip / Hot Line Tag allows instantaneous opening.

- Programmable handle delay allows time to walk away before device closes in the event the fault is still present.

Versatility

- Remote programmable in-service design allows easy reprogramming for any system coordination changes.

- Inventory reduction through one-size fits all design up to 29.6kV.

- Four product types to fit application needs all having the same base footprint and basic functionality.

Protection

- The Versa-Tech is voltage independent and utilizes current harvesting technology along with fault current to perform reclose operations without minimum line current restrictions.

- The Versa-Tech can function, perform programmed protection operations, and lockout from a deadline condition without the need for external power or battery power.