A new house was constructed in West Virginia, but within a year it was clear that one corner of the house was dropping. Not good, but not unusual in an area known for its coal mines. By the time the ground stabilized, one basement wall was damaged beyond repair and the wood-framed house above was out of square and damaged.

Robert A. Smith, P.E., owner of Engineered Foundation Solutions, PLLC in Wheeling, WV, explains, “In this area, mines extract coal with a long-wall mining machine. They take out the entire coal seam and let the earth above collapse down into the void. The mines are deep –maybe 800 feet underground – and there is no way to know how much the surface of the soil will subside. Some homes above mines are not affected at all, others are significantly damaged, some are catastrophically damaged and must be torn down and rebuilt. In this case, the land under one corner of the new home dropped by 4 inches, which is repairable.”

Mine subsidence and the resulting damage are common in the area and Engineered Foundation Solutions regularly does remediation work, but repairs do not begin right away. “We first visited the site and took readings with a laser level. The house was definitely subsiding, but for a coal mine issue we always advise our customers to wait at least two years before doing any type of remediation work in order to allow the ground to settle.” When that time had elapsed, they were called back to re-evaluate the situation. One of the basement walls was catastrophically damaged and had to be replaced and along with another wall, supports were needed for stabilization.

The engineering design for the Atlas Resistance® Piers was performed by S&P Engineering, Inc., a sister company to Engineered Foundation Solutions. Fortunately, the soil at the residence was nearly perfect and each of the 12 piers met the required resistance at nearly the same depth – 7 feet.

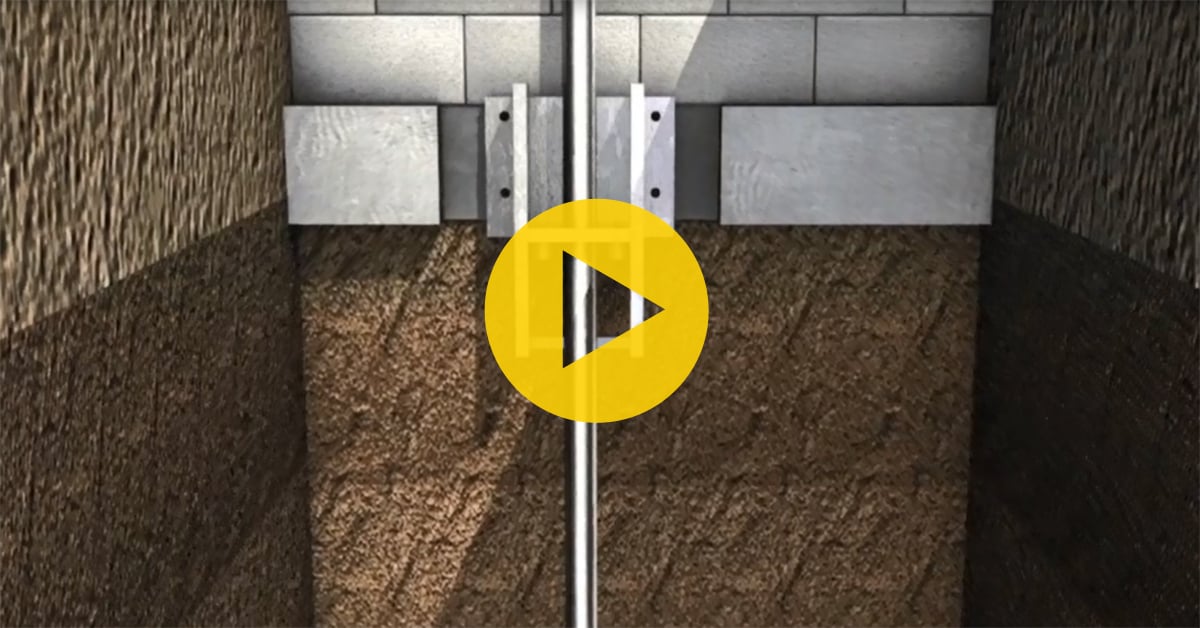

Watch a video showing how push piers work to repair a foundation:

Work conditions were good, but the customer had some requirements for installation. The homeowners had just poured a new concrete driveway and sidewalk as well as recently had a new deck installed. Naturally they did not want any large machinery on-site tearing up the new additions. “This wasn’t a problem because Atlas Resistance Piers don’t require big machines and, obviously, we could not get a big machine into the basement, anyway,” explains Smith.

Atlas Resistance piers were installed outside of the house along one wall and inside the basement along another wall. To get to the footer, workers dug down on the outside of the house and cut through the concrete floor in the basement. Workers undermined the footer, where necessary, to mount the brackets and prepare for pile installation. The bracket is bolted to the underside of the footer and extends out besides the footer. The piers are installed vertically, through the bracket. Unlike helical piles, which are screwed in, Atlas Resistance piers are pushed into the ground hydraulically.

Atlas Resistance piers were installed outside of the house along one wall and inside the basement along another wall. To get to the footer, workers dug down on the outside of the house and cut through the concrete floor in the basement. Workers undermined the footer, where necessary, to mount the brackets and prepare for pile installation. The bracket is bolted to the underside of the footer and extends out besides the footer. The piers are installed vertically, through the bracket. Unlike helical piles, which are screwed in, Atlas Resistance piers are pushed into the ground hydraulically.

Smith explains, “You use a hydraulic driver with a piston. The weight of the structure supplies the that opposite reaction and it forces the pier into the ground.”

Smith and his team installed 12 piers that were all 3-1/2 inch diameter round pipe piers and each installation required one extension rod.

The piers are driven in until the desired PSI rating is reached. At this home, the design called for 4,500 PSI. All but one reached 5000 PSI at 7 feet. That works out to about 44,700 pounds of support per pier.

Work started in late September and was completed in a week.

In this case, the resistance piers were the best, but not only, solution. Smith points out, “When it comes to mine subsidence, a steel piering solution, such as helical piles or resistance piers, has always been the best solution, hands down. However, in the customer’s eyes, it is not always the least expensive solution. So, we compete against the contractors who will basically come in, tear out a foundation wall or concrete footing, and start over again. My concern as an engineer is that just replacing the concrete footing doesn’t guarantee the soil is stable underneath the footing.”

Besides guaranteed stabilization, another major benefit for these homeowners was low vibration and minor noise. “We installed while the homeowner was sleeping after working the night shift. He came home at 7:00 AM, went to bed, and slept while we worked. Once we got the footer chipped away, the only noise was from the hydraulic ram, which is about as noisy a household generator sitting in the yard,” explains Smith.