The YMCA Downtown Pensacola has a busy aquatic center open to all including kids learning to swim, teen lifeguards receiving training, and adults who enjoy the health benefits that swimming and water aerobics offer. None of these benefits to the community would be available if the facility’s two pools weren’t first established on a stable foundation.

Working with local distributor Foundation Technologies, Inc., Chance Certified Installers from Mason Grady Foundations, a family owned and operated deep foundation construction company, were entrusted with the entire design-build process for this important project.

Complex Soil Counts

The project faced a tight production timeline with complex soil counts. The site had a soft layer of sand for the first 10 to 15 feet and below that was approximately 20 feet of extremely dense organic clay.

The team at Mason Gray had to find a foundation solution that would be able to penetrate the dense clay and provide adequate capacity for the pool foundations. The teamed turned to Chance square shaft (SS) piles for their design.

Chance square shaft piles are a high-torque, shaft driven, multi-helix deep foundation. Square shaft is the overall best choice for helical piles designed to support design loads up to 50 kip. Square shaft piles have slender cross sections so they will not resist much lateral load. Shaft buckling is not a problem so long as the soil surrounding the shaft is firm. Engineers and contractors are encouraged to use square shaft helical piles as much as possible due to their advantages with torque correlation efficiency and better penetration in dense soil. They are also the easiest and fastest to install.

Chance square shaft material is a solid steel shaft with at least one helix plate welded to it. They come in sizes from SS5 (1-1/2 inches) to SS225 (2-1/4 inches).

Mason Frascona, with Mason Grady Foundations, shared, “[The density] was enough to almost max out the SS225 material which is why we had to go with the larger material to get through that layer and the soft layer below, reaching the 75 ft. depth. There wouldn’t have been another way to penetrate that dense layer.”

To further complicate the design, the soil boring showed a high water table at approximately 4 feet, which, combined with weather, could create a large excavation full of water and delay the entire project, which faced a tight production timeline.

Pulldown Pile Solution

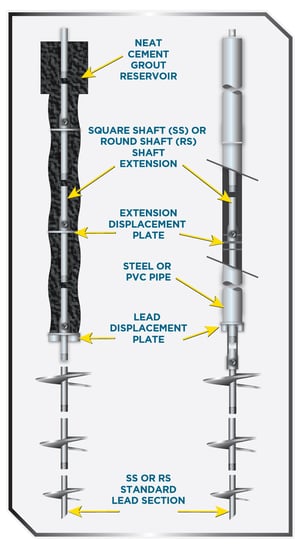

Chance Helical Pulldown Micropiles (HPM) provided the best solution for this project. This deep foundation solution constructs a grout column around the shaft of a standard helical pile foundation system. This time- and labor-saving product is installed directly into soil. A lead displacement plate eliminates the need for excavation and spoil removal from the job, allowing for 40-50 piles to be installed per day with smaller crews and equipment. The grout column results in a higher capacity pile system (greater than 100 tons possible) that is ideal for weak soil sites with limited access.

Chance Helical Pulldown Micropiles (HPM) provided the best solution for this project. This deep foundation solution constructs a grout column around the shaft of a standard helical pile foundation system. This time- and labor-saving product is installed directly into soil. A lead displacement plate eliminates the need for excavation and spoil removal from the job, allowing for 40-50 piles to be installed per day with smaller crews and equipment. The grout column results in a higher capacity pile system (greater than 100 tons possible) that is ideal for weak soil sites with limited access.

Excellent for projects where increasing capacity and providing predictable results is a must, the HPM provides a stiff pile that resists buckling in weak soils while also providing corrosion protection in aggressive soils and high water tables. A proven engineered system, bearing and side resistance is combined to bring a no pre-drill solution to a wide variety of applications for new construction, remedial repair, and limited access areas with minimal site disturbance.

The final design called for the square shaft piles to be encased in a gravity-filled grout column, forming a Helical Pulldown® Micropile. A Pulldown Pile is a helical pile that has the steel shaft section encased in a small diameter grout column, typically 5” - 7” in diameter. It has the advantage of the square shaft pile to penetrate dense material for end bearing, plus the grout column provides greater section properties for shaft stability and lateral resistance in soft soils. In addition, the grout column provides additional capacity from friction along the sides of the shaft in contact with the soil. Pulldown Piles are often used when design loads exceed about 60 kip. A load test was conducted prior to the installation of production piles to verify the pile capabilities. Even at 200 kips, pile movement was less than a half inch.

👉 Read about another low-deflection design

Foundation Installation

The piles for the pool foundation were installed with a 28,000 lb. excavator running a 30,000 ft-lb Digga drive head. There was limited access to the site, and the excavator entered the work area through a 10 ft. wide by 18 ft. high opening. Helical piles can be installed with smaller equipment such as mini excavators that can be maneuvered into tight spaces if required.

The General Contractor wanted to minimize the amount of time that the crew would have to work around the pool excavation. Therefore, they excavated the pools and installed the piles near the end of the project, after the roof was complete.

The working load was as high as 97 kips in compression and 54 kips in tension. The crew installed SS225 piles with a 8/10/12/14 helix and a 7-inch grout column to a depth of approximately 75 feet, with torque values from 10,000 ft-lbs. to 20,000 ft-lbs. Torque was measured with a Chance Torque Indicator. This tool provides an instant readout of installation torque, allowing the operator to confirm the capacity of the installed pile. As mentioned, square shaft piles provide the most accurate torque-to-capacity relationship, giving engineers and contractors confidence that the designed foundation will perform as expected.

The contractor estimates the use of helical piles saved six to eight weeks and, since the excavation and installation could be completed after the roof was in place, prevented project delays due to weather. The pile installation was the third Helical Pulldown Micropile project that the installers completed, and they found the piles easy to work with.

When doing a helical pile installation, it’s important to make sure the piece of equipment that is being used is appropriate for the size drive-head and material being used, to ensure that the proper penetration rate and crowd can be maintained during installation.

👉 Learn more about equipment selection

In total, there were 36 Chance Helical Pulldown Micropiles installed across the two YMCA pool locations and the installation took only eight days to complete.

Key benefits:

- Limited access

- Quick installation

- Penetration through dense soil count

- Easy to use

- Low to no vibration/noise

- Standard equipment for installation

- Immediate proof testing and loading