Although concrete is ubiquitous in construction, it doesn’t necessarily mean it’s always the best material for the job. “But we’ve always done it this way!” is a dangerous reason not to investigate new ways of doing things. Okay, so helical piles aren’t exactly new. Their first recorded use was in 1836 when engineer Alexander Mitchell used them for a lighthouse foundation. But compared to the first concrete being used in ancient Rome, helical piles are like a teenager in the foundation world (although not at all temperamental and definitely more reliable).

Helical piles have many uses and you can read about some of them here in our blog, including:

In this article, we’re going to focus specifically on wired foundations, meaning foundations for things that will require conduit and an electrician to complete the job. Also known as Chance Instant Foundations®, some applications for wired foundations include:

-

-

-

Light poles

-

EV Charging Stations

-

Bollards

-

Signage

-

Solar array pole mount

-

5G Poles

-

End zone tower system

A “new” way: Steel helical piles for wire-ready foundations

Although we all probably know a local source for concrete, or can find out quickly with a little help from Google, is that really the easiest way? Specific to applications requiring wiring, which may not demand a full load of concrete, installers have been faced with long wait times, or even outright refusal, to get the material required to complete installations of light poles, EV charging stations, and more.

Chance Instant Foundations have a cableway cut into the steel pipe shaft. A pilot point and helix at the end of the shaft allow the foundation to be quickly and easily screwed into the ground, aligned with the conduit trench, loaded, and wired. Watch an installation:

Is this foundation faster than concrete?

Everyone has something more important to do than watch concrete cure (It’s probably even lower on the list than watching paint dry). This last “What Matters” article for the year, Family Matters, is probably the most important… no one wants to be stuck on a jobsite waiting for concrete when they could be spending time with loved ones.

Here are some ways Instant Foundations will help you get the job done and move on to more important things:

-

-

You won’t wait on material. Ranging in sizes from 3 feet to 10 feet long, Instant Foundations can be stored by an installer or a local distributor, ready to pull from inventory and transported to a jobsite when a job requires a wire-ready foundation.

-

You won’t wait on the weather. Instant Foundations can be installed during rainy, even freezing, weather conditions. Without excavating, they can be screwed through most soils and loose blacktop surfaces. Even in the densest, rockiest soils, Instant Foundations can be used after a hole is augered.

-

You won’t wait to load and wire. With no cure time, an Instant Foundation can be installed and leveled in an average of 10 minutes with a two-person crew –

-

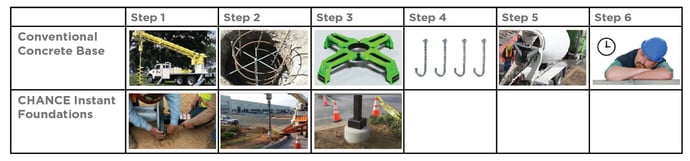

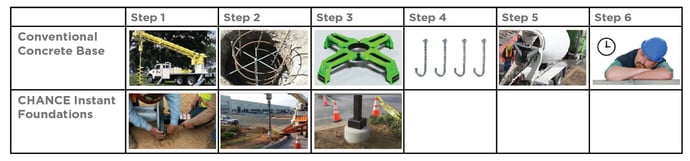

Once the foundation is installed, it can be immediately loaded and wired. No J-hooks, no expensive anchor bolts, no spoils to clean up. Here’s a brief summary in pictures:

Get started now

Be the hero of your company – the one who says, “I know we’ve always done it that way before, but here’s something that would be faster and more efficient.” We’re here to help.