UPDATE FOR 2025: Now simplify tieback jobs even more with the Chance Universal Adapter. Transition from a square shaft helical pile to any 1" threaded bar and drive on it until termination.

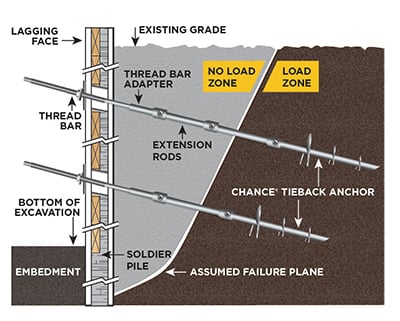

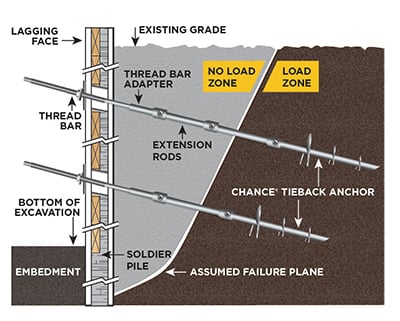

Chance® helical tiebacks are a pre-engineered mechanical anchoring system for permanent and temporary shoring. The success of the helical anchor tieback system is based on decades of similar use of Chance anchors in the electric utility industry. Capacities up to 200,000 pounds per anchor are obtainable with this “instant” tieback shoring method. Chance tiebacks offer a fast, cost-effective and simple solution for any tieback project.

Let’s do a comparison of the three main advantages of Chance tiebacks versus the conventional grouted tendon methods:

-

No excavation required (Spoils free)

Helical tiebacks are installed into retained soil with commonly available hydraulic rotary drilling equipment. No excavation is required and, therefore, no spoils. There is no need to find a suitable location to dispose the soil. This could be especially of interest if there is an environmental concern on the project site . Also, for chemical-contaminated soil, a proper disposal and treatment is required. With helical tiebacks, this factor is eliminated, reducing the overall schedule and cost.

Immediate proof testing and loading

One of the best advantages of helical tiebacks is that they can be immediately loaded and tested. Grouted tiebacks, have to be drilled and grouted , and often post-grouted; before waiting at least 3-5 days for the grout to cure to start proof testing. For the helical tieback, the capacity is predicable by torque correlation, that is recording the installation torque and using a correlation factor (Kt) to predict the holding capacity based on shaft type. The greater the installation torque, the greater the axial capacity. Unlike other shoring methods, helical tiebacks allow the anchor length and helix bearing area to be adjusted in the field to meet the specified load requirements for site-specific conditions. Once the installation is finished, a threaded bar is connected to the tip of the helical anchor and the system is tension proof-tested to the required load. Note that, with helical tiebacks the load is transferred by end bearing - not skin friction - so most of the time the helical tieback can be terminated at a shorter length compared to a grouted tendon tieback.

One of the best advantages of helical tiebacks is that they can be immediately loaded and tested. Grouted tiebacks, have to be drilled and grouted , and often post-grouted; before waiting at least 3-5 days for the grout to cure to start proof testing. For the helical tieback, the capacity is predicable by torque correlation, that is recording the installation torque and using a correlation factor (Kt) to predict the holding capacity based on shaft type. The greater the installation torque, the greater the axial capacity. Unlike other shoring methods, helical tiebacks allow the anchor length and helix bearing area to be adjusted in the field to meet the specified load requirements for site-specific conditions. Once the installation is finished, a threaded bar is connected to the tip of the helical anchor and the system is tension proof-tested to the required load. Note that, with helical tiebacks the load is transferred by end bearing - not skin friction - so most of the time the helical tieback can be terminated at a shorter length compared to a grouted tendon tieback.

Removable & Reusable

Helical tieback anchors can be easily removed and reused. This is especially beneficial for temporary tiebacks in jurisdictions that don’t allow tiebacks going into the adjacent property or under the street (For example, the City of Los Angeles and Redwood City, CA). Removing a grouted bar tendon tieback is extremely difficult. If anything goes wrong during the installation, the grout will leak inside the un-bonded zone of the bar tendon (PVC zone) and it will be almost impossible to remove that tendon. On the other hand, if helical tiebacks are used, they can be easily un-screwed out of the ground. Also, they can even be reused in another project site, depending on the application.

In addition to these main points, other items that give helical tiebacks an edge over grouted tendons is there is no need for dewatering for below water table applications. Helical piles can be installed with smaller equipment - even with the same equipment that would be used for a grouted tendon. Additionally, no casing or grouted sock is needed when working on non-cohesive soils, and no concrete or grout pump is required.

Remember that the use of cement itself is extremely hard on the environment. The cement industry is one of the largest contributors to greenhouse gases on the planet. As the world shifts to eco-friendly construction solutions, a tieback system that will not involve the use of grout is a win-win for everyone. Read more about sustainability with helical piles.

Start designing helical tiebacks with predictable capacity in HeliCAP® helical capacity design software today.

One of the best advantages of helical tiebacks is that they can be immediately loaded and tested. Grouted tiebacks, have to be drilled and grouted , and often post-grouted; before waiting at least 3-5 days for the grout to cure to start proof testing. For the helical tieback, the capacity is predicable by

One of the best advantages of helical tiebacks is that they can be immediately loaded and tested. Grouted tiebacks, have to be drilled and grouted , and often post-grouted; before waiting at least 3-5 days for the grout to cure to start proof testing. For the helical tieback, the capacity is predicable by