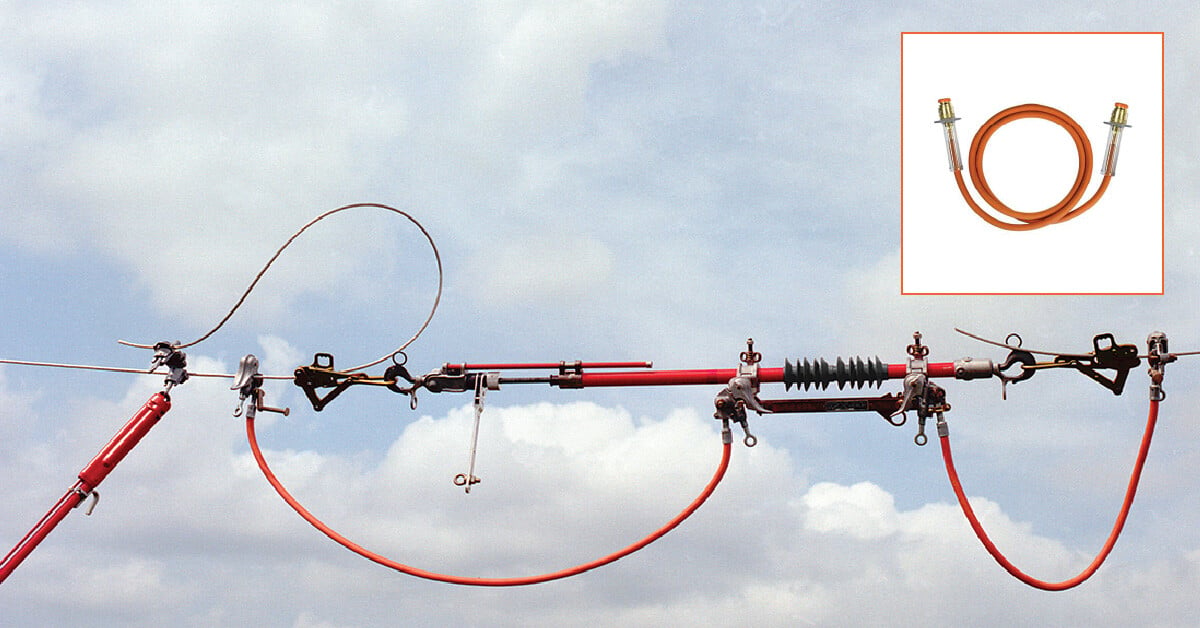

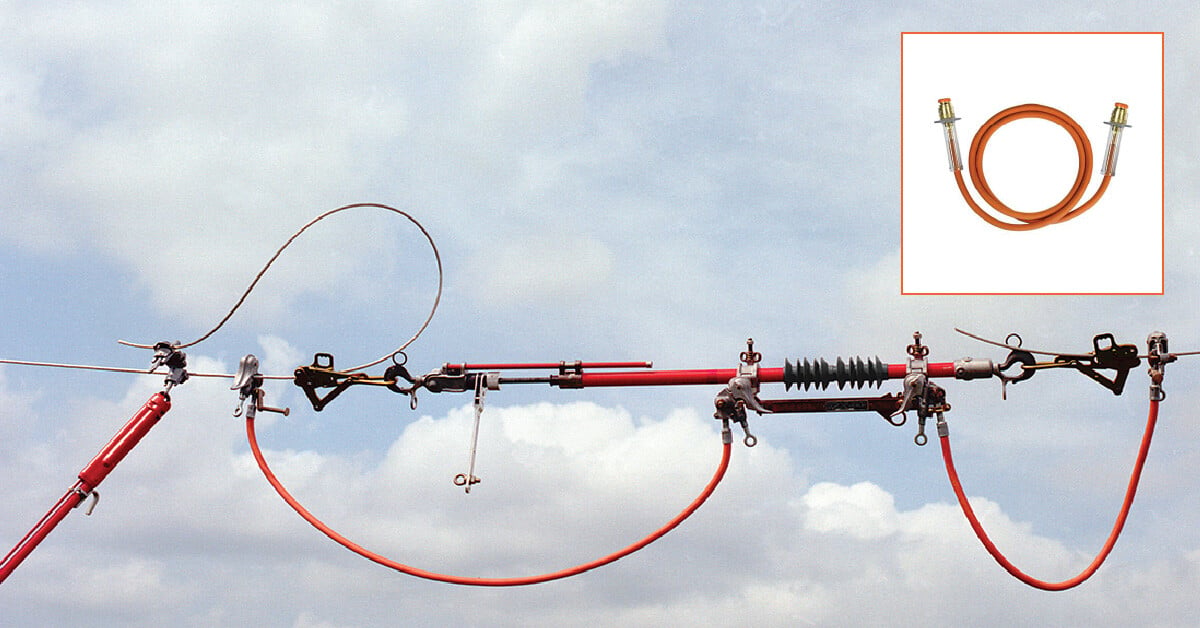

Every day, Line Workers around the world utilize hot line tools to perform live-line energized maintenance. One common tool used for live-line maintenance is the insulated temporary jumper set. There are also temporary load pick-up sets and rigid bypass jumpers that perform similar duties for electric utilities. These sets can be provided with mechanical style rubber glove jumper clamps or utilize temporary grounding clamps for attachment to energized conductor to create a parallel circuit. The crimped ferrules for each style differ depending upon which clamps are used. Jumper cables are rated per maximum use voltage (15, 25, or 35kV) and current carrying capacity is dependent on the size of the wire (#2, 1/0, 2/0, and 4/0) and clamps chosen. CHANCE® temporary insulated jumper sets are designed, tested, and manufactured per ASTM F2321.

Assembly

Using the correct ferrule and crimper ensures the correct assembly of a temporary insulated jumper or load pick-up set. There are special short ferrules in the Jumper and Load Pick-Up Catalog Section for load pick-up tools and mechanical style rubber glove jumper clamps. Temporary Jumper sets that use grounding clamps use unshrouded grounding ferrules that can be found in the Temporary Protective Grounding Catalog Section. CHANCE factory assembled flexible and rigid jumper and load pick-up tool sets use a circumferential crimp to attach the ferrules to the jumper cable. Directions are also given for using Burndy™ crimpers with jumper ferrules or grounding ferrules. The nut that tightens down on the grounding clamp or mechanical rubber glove jumper clamp should be tightened to 250in-lb. There is also a set screw that must be tightened down on the mechanical rubber glove jumper clamps to ensure proper assembly.

Visual Inspection

Each day before use, jumper and load pick-up tool sets should be visually inspected for damage per ASTM F2321 Section 46. The cable should be inspected for broken strands, swelling, and cracks or other damage to the jacket of the cable. The clamps and ferrules should be inspected for loose or missing hardware, cracks, or other damage. If damage is found, the jumper or load pick-up set should be removed from service and repaired. Once repaired, the set should be tested before returning to service. If hardware is missing, it should only be replaced with factory supplied components. The load pick-up tool sets also require disassembly, cleaning, and inspection every 25 uses or 90 days. If the Epoxiglas™ tube on a rigid bypass jumper or the insulated jumper cable surface becomes dirty, please clean per factory recommendation before use.

Periodic Electrical Testing

The factory recommends that an annual test be performed for electrical recertification of the temporary insulated jumper or load pick-up set cable insulation. The test should be conducted in accordance with ASTM F2321 Section 45.2 for a duration of 1 minute. The jumper set should be visually inspected per ASTM F2321 Section 46 and cleaned prior to electrical testing. Moisture Eater II can be used to clean the jacket of CHANCE insulated jumper cable. The AC or DC proof test voltages can be found in Table 5 of ASTM F2321.

CHANCE rigid bypass jumpers should be electrically tested annually per Figures 11 and 12 in ASTM F2321.

Considerations For Use

When temporary insulated flexible or rigid jumper or load pick-up sets are used, they may inadvertently contact other line equipment at different potentials. It is a common industry practice to use a piece of CHANCE cover-up to provide a second layer of insulating protection against this possibility. For example:

- Using a flexible or rigid crossarm cover to lay a jumper cable across a crossarm.

- Using a rubber blanket to cover a crossarm where a rigid bypass jumper lays on a crossarm.

- Placing rubber blankets over deadend insulators and hardware where a jumper cable is in contact with the equipment.

- Using a pole cover where an insulated jumper cable is in contact with a pole.

Jumper and load pick-up tool sets are intended for temporary use only and should only be installed for a maximum of 72 hours.

Remember that the lowest rated component of the temporary jumper or load pick up set will determine the maximum use voltage and current rating of the set.

Storage

Temporary flexible jumpers, rigid bypass jumpers, and load pick-up tool sets should be stored in a bag while not in use. Keep the sets away from water, contamination, or chemicals that could damage the insulation of the jumper cables.

Contact CHANCE for Questions

CHANCE temporary insulated jumper and load pick-up tool sets are exceptional tools for performing energized line maintenance. For additional questions or to schedule training with a CHANCE expert on temporary insulated jumper and load pick-up tool sets, or any other product, please reach out to your local Hubbell Utility Solutions’ Territory Manager or contact our training team by filling out this form.