What does it take for a product to become a market leader in the electrical power market? It takes years of research, superior design and construction, and proven performance. Polymer deadend insulators (PDIs), manufactured by Ohio Brass®, a subsidiary of Hubbell Incorporated, are the clear market leader, selling over one million units per year.

What are Polymer Deadend Insulators (PDIs)?

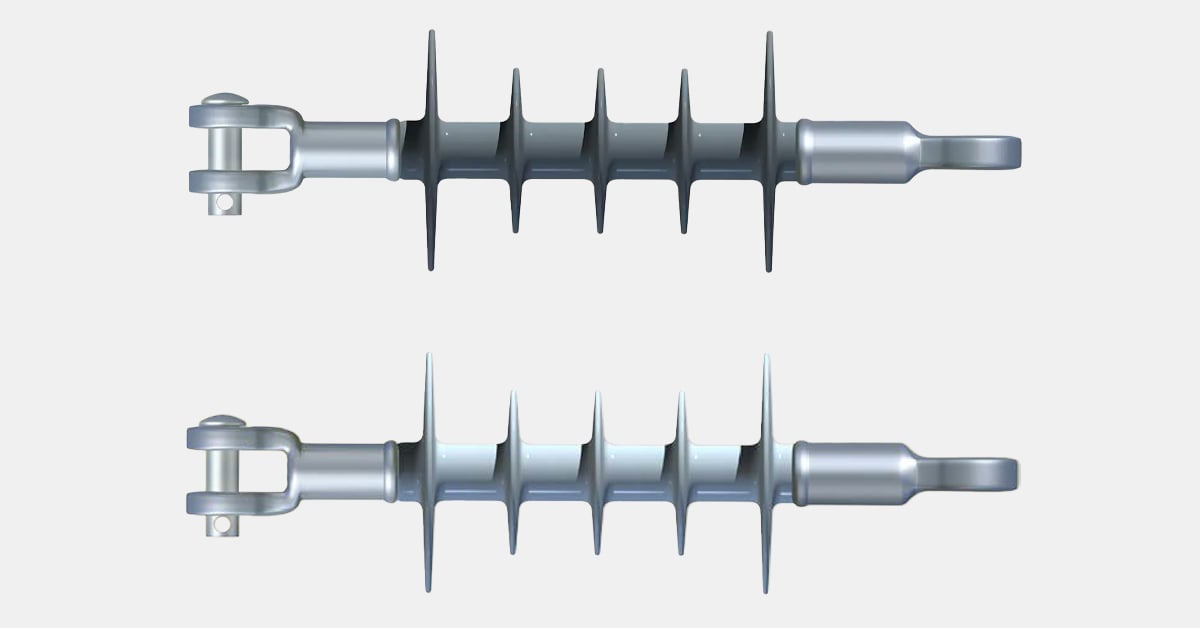

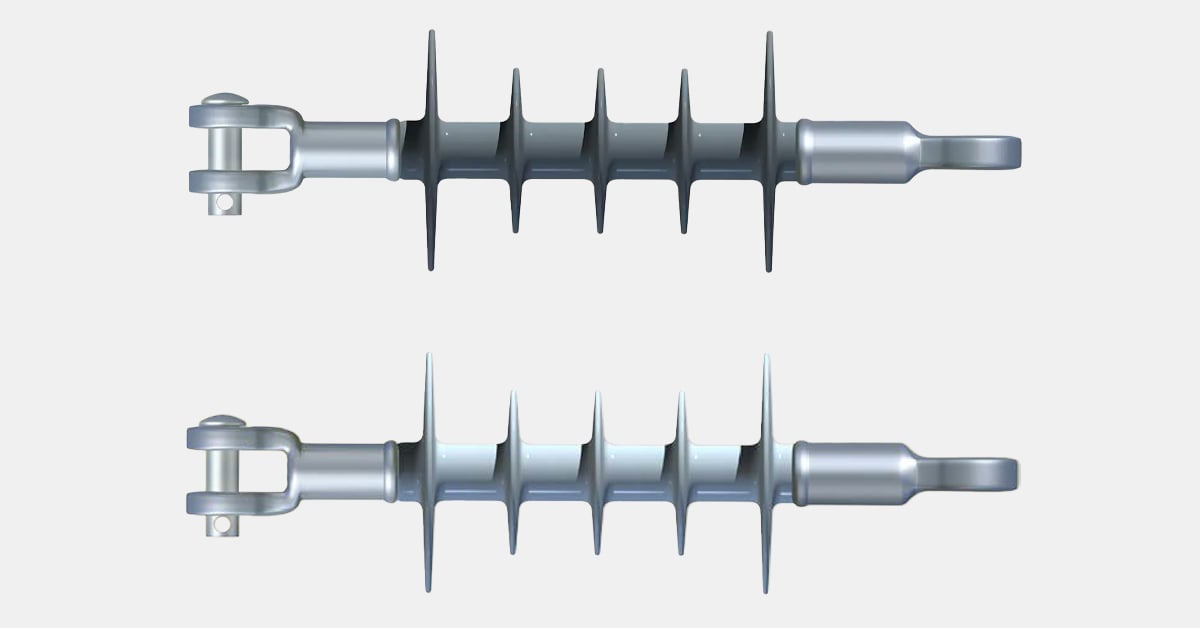

Polymer dead end insulators are mechanical devices used in an electrical environment for overhead distribution lines to support and isolate the phase conductors and prevent current flow to ground. They have different voltage ratings and end fittings depending on the application. The PDIs are offered for distribution dead end applications in the voltage range from 15kV to 46kV. This product line has an offering for several DS class ratings, ranging from a DS-15 to DS46 rating.

Track Record of High Voltage Insulator Research

Ohio Brass began it's research into polymer applications in the early 1960s. This led to the introduction of its first polymer transmission Hi*Lite® insulator in 1976, followed by PDV-100, the first US-made polymer housed metal oxide varistor (MOV) arrester. Decades of research have produced the current offerings – insulators made with a choice of two proprietary polymer compounds, ESP™ and silicone polymer. Our PDIs are backed by thorough testing and research to provide our customers with high performance products.

Superior Design and Construction

Hubbell's PDIs are distinguished by their superior design and construction. All PDIs are tested in accordance with ANSI C29.13 and CSA C411.5-10 standards.

Fiberglass Reinforcement for Maximum Strength

The fiberglass rod, made from high-quality materials, is filled with electrical-grade corrosion-resistant glass fibers for maximum tensile strength.

Innovative Crimping Process for Structural Integrity

The ferrous end fittings are directly crimped to the rod using a circumferential crimping process originated by Ohio Brass, ensuring high strength without the need for potting compounds or adhesives.

Proprietary Polymer Compounds

ESP rubber is a combination blend of EPDM and silicone rubber, which is the same polymer compound used today in our PDV arresters and polymer cutouts. The option of PDIs with our weather-resistant silicone rubber with superior hydrophobic properties, which is the same proven material used in our Quadri*Sil Transmission Insulators.

The Market Choice

Different geographical locations and environmental conditions call for different materials in deadend insulators. Superior research, design, construction, and performance have led to more than 40 million polymer deadend distribution insulators currently in service. Experience the difference firsthand and upgrade to Hubbell Ohio Brass PDIs.

Find Out More about Transmission and Distribution Insulators

All our products are readily available, Learn more about PDIs at Hubbell Power Systems Insulators Educational Series Library or explore our broad range of insulator offerings.