As the summer peak approaches in early August, utilities need to make sure they are ready to handle the increased load. Peak electricity demand refers to the time period when the most power is consumed throughout the entire electricity network system. It is concentrated to a few hours of the year during very hot summer afternoons.

These hot summer afternoons are a recipe for electricity peaks because of limited load diversity — air-conditioning units are on full blast, businesses and factories are operating at high capacity, and household appliances are running all at the same time.

The summer peak puts a tremendous strain on the electricity grid, increasing the risk of blackouts and brownouts. Utility companies must manage the increased load on their circuits and transformers to avoid an overload. One way that utilities can monitor the increased load is by installing Aclara Grid Monitoring (AGM) sensors with load monitoring capabilities.

Load monitoring of circuits and transformers

By installing AGM sensors on your unmonitored substations, capacity planners gain real-time accurate data about the real load on your circuits. When a circuit becomes overloaded, it may cause the circuit breaker relay to trip on load current. Outages can also occur on the distribution line when an overloaded jumper or splice fails. By having load monitoring data, you can make quick, informed decisions that help prevent outages before they occur. The sensors work by providing an early warning when the circuit is about to be overloaded.

When a problem is detected, the AclaraONE® grid monitoring software platform sends an alarm to the utility’s SCADA system or by email to indicate when the load is approaching a dangerous threshold. When the warning is received, the utility can implement its contingency plan by switching the load to other circuits or implement a demand response (DR) program. By having these alarms, utilities can avoid costly outages that would have occurred without load monitoring data.

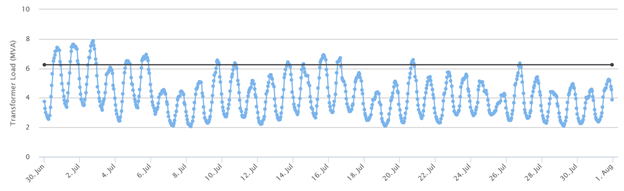

In addition, the sensors can monitor the transformer loads as shown in Figure 1. Heavily loaded transformers have poor voltage regulation, which results in lower bus voltages. This voltage drop is particularly troublesome during the summer peak because the system’s voltage is already low due to high system loading.

Figure 1. Smart grid sensors can monitor transformer loads, providing insight into the effect summer peak loads have on voltage regulation.

Under these conditions, AclaraONE will display and compare the aggregate loading of all circuits being supplied by a transformer to the rating of the transformer. Three summer and three winter alarms can be set up in the platform to provide immediate notification of a pending overload.

Field engineers are extremely busy during the peak trying to keep the voltage within acceptable ranges. When field engineers are searching for the source of the drop, AGM sensors can help by telling them if the transformer is the cause. This helps engineers discover the cause of the voltage drop quicker and solve the issue faster.

DR and CVR systems

Load monitoring is not the only way AGM sensors help utilities during the summer peak. Sensors are also used to determine the value of DR and conservation voltage reduction (CVR) systems. DR and CVR programs are installed to help reduce the amount of electricity used during peak times. However, if DR or CVR programs are installed on unmonitored substations, utilities do not have concrete evidence that these programs are working.

Recently, a utility installed AGM sensors to monitor a substation to prove the effectiveness of a DR project it had initiated at a commercial building. The utility used the sensors to measure the load on the substation when the DR system was on and when it was off. By comparing the loads, the utility measured the effectiveness of the DR programs. Utilities can use this information to guide capital expense project planning. Having concrete evidence to prove the success of a DR program can save utilities’ money by allowing postponement or canceling of costly capital projects such as adding more circuits or upgrading substation transformers.

Utilities also install the AGM Sensors in CVR deployments to provide real-time measurements into their CVR software. By measuring the primary voltage to within 0.5% accuracy across the full temperature range (-40°F to +140°F), the CVR software can confidently lower the voltage and extract more KWH savings out of the system without risking a low voltage condition.

Fault detection and location

In addition to monitoring issues surrounding summer peak, once AGM sensors are installed, you can take advantage of their fault-detection capabilities, including knowing exactly where faults, momentaries and outages are occurring. With sensors in place, you can detect the fault and pinpoint the location of where the outage occurred, for example during a bad summer storm. Fault detection and location capabilities help you restore the outage faster, saving you time and money.

So, don’t sweat this year’s summer peak. For more information, download a case study about how NV Energy uses AGM sensors to monitor its distribution network.