Have you ever gotten stuck in traffic? You know there’s a problem, but you can’t see far enough ahead to know what it is or the best options for avoiding a three-hour delay.

Electric distribution engineers face a similar problem. The decades-old substations and major distribution lines that dominate the electrical grid do not provide the data – such as electricity flow, voltage fluctuations and more – that are necessary to manage the distribution network and identify momentaries, prevent power outages and improve reliability, especially in older parts of the system.

To balance the system, anticipate customer demand, resolve power-quality issues and get an accurate picture of network activities requires data. But distribution engineers are often faced with the challenging task of identifying cost-effective solutions to monitor their distribution network.

What’s a Utility to Do?

Utilities have many options for monitoring distribution substations and circuits. Some involve devices used for basic recording or studies, such as faulted circuit indicators (FCIs), load loggers, or power quality analyzers. Others involve remote monitoring and usually entail the use of various combinations of Supervisory Control and Data Acquisition (SCADA), monitoring of substation relays, reclosers, switches, or other remote terminal units (RTUs), controllers, or even line post sensors, current transformers (CTs) and voltage transformers (VTs) with meters or power quality analyzers.

These traditional approaches provide a significant amount of data to distribution network engineers but also have limitations:

- Accuracy– These solutions require on-site calibration and are unable to filter out false alarms, which means that they sometimes provide an inaccurate picture of grid conditions. Utilities can incur significant costs rolling trucks to respond to false alarms.

- Hidden Costs— Employing the equipment and processes required to deploy traditional monitoring methods can become burdensome on OPEX budgets. For example, FCIs require battery replacement and maintenance, so utilities must deploy crews to locate each FCI and replace the batteries. These costs add up.

- Reach and visibility— The volume and quality of data collected and delivered back to utility engineers are limited in many cases.

- Point solutions– Temporarily installed devices that analyze parts of a circuit provide only a limited view of the system’s overall health.

Installing telemetry solutions is also time-consuming and expensive, requiring the design of the metering and communications, equipment procurement and scheduling and full crews to do the installation work. In addition, outages will occur during installation, and the utility must plan a communications program to manage customer expectations. And when remote customers do not have alternative lines to serve them, they will remain without power until the equipment is installed and power can be restored.

Continuously Providing Reliable Service – NV Energy

NV Energy is the largest electric utility in Nevada, providing electricity to 1.2 residential, business and industrial customers, or almost 90 percent of Nevada’s population, and over 40 million tourists annually. Much of the state’s electrical infrastructure was designed initially to support a much smaller population, and the increased customer demand, coupled with the use of older equipment in much of the electrical distribution infrastructure, makes it difficult to understand the status of circuits before overload conditions arise.

NV Energy is the largest electric utility in Nevada, providing electricity to 1.2 residential, business and industrial customers, or almost 90 percent of Nevada’s population, and over 40 million tourists annually. Much of the state’s electrical infrastructure was designed initially to support a much smaller population, and the increased customer demand, coupled with the use of older equipment in much of the electrical distribution infrastructure, makes it difficult to understand the status of circuits before overload conditions arise.

Like many other utility companies, NV Energy maintains and operates a combination of modern and older electric grid infrastructure. The company consistently ranks in the top 25% of utilities in reliability, and substations and distribution power lines are two of the company’s most valuable assets to support reliable electrical service.

As part of its continuing effort to maintain a high level of reliable services to its customers, NV Energy sought to monitor substations and power lines for overload conditions without labor-intensive overhead and coordination with multiple departments. The company also wanted a solution that could be activated quickly and installed with minimal interruption of service, with clear benefits to NV Energy’s customers.

Grid Monitoring Platform with Smart Grid Sensors

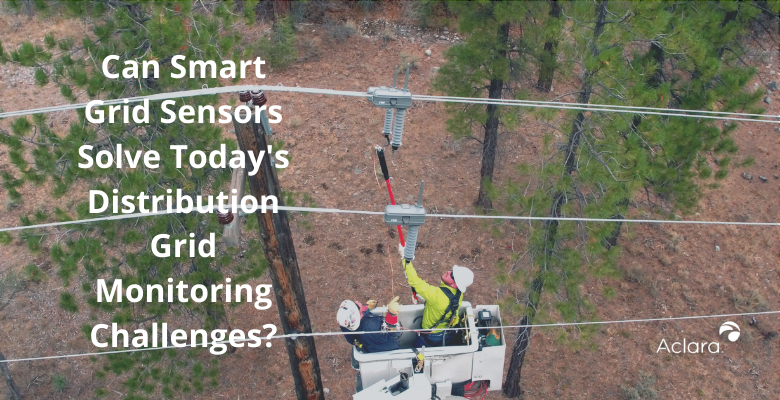

To meet its needs, the utility selected the Aclara grid monitoring platform. The solution includes software-defined, inductively powered, battery-free, medium-voltage line sensors and software with Predictive Grid® Analytics. Hotstick deployable, smart grid sensors quickly clamp on onto the lines, a safer process for linemen.

The technology provides immediate, real-time data capable of alerting network operators to potential problems on the network. It enables utilities, such as NV Energy, to predict outages and locate major faults before they even occur.

Data collected by the grid monitoring solution helps NV Energy improve its service reliability. For instance, NV Energy deployed a combination of medium-voltage sensors and power sensors in a remote area of the distribution system where the utility has little visibility into grid conditions. Within days, the sensor information revealed a weakness in the area’s network infrastructure. The NV Energy team was able to address the problem immediately.

“This technology enables us to modernize and monitor our network in a very cost-effective way and helps us develop new approaches to prevent power outages and improve restoration time when electric system anomalies occur. We are pleased that this technology also easily integrates with existing monitoring systems at NV Energy, which allows our teams to share data and work collaboratively,” said Pat Egan, senior vice-president of customer operations, in a press release issued by NV Energy.

NV Energy found that new methods such as Aclara’s grid monitoring solution provide safe, simple integration into multiple utility applications while providing lower costs and fewer service disruptions than traditional monitoring systems. The real-time data collected by the system provides actionable information they can share across multiple departments.

Distribution monitoring solutions offer groundbreaking technology to utilities, combining smart-grid sensors and predictive analytics to support grid engineers as they bridge the gap to a modern grid.