This is Part 3 in our 4-part series on why sensors are a better investment than fault current indicators (FCIs, or FPIs in Europe). Here is a recap on what we discussed so far:

-

Part 1: The short falling of FCIs in meeting utilities’ needs for real-time monitoring

-

Part 2: With real-time data from the distribution grid utilities can proactively troubleshoot future failures by looking for the precursors of problems before they cause an outage

-

Part 3: why data collected by smart grid sensors can provide better identification of faults on both feeders and laterals

In this post, we will focus on the third reason why utilities should choose sensors vs FCI:

Smart Grid Sensors can be used for multiple applications,

while FCI’s are a single-purpose point product

FCIs alert utilities of the presence of a fault. Therefore, by installing FCIs utilities are resolving only one of many pain points related to getting real-time data from their distribution grids to improve reliability. On the other hand, utilities that install the Aclara Grid Monitoring Platform can take advantage of many different use cases, or applications, that improve grid reliability and reduce operational expenses.

Aclara smart grid sensors offer more than fault detection

Utilities rely on Aclara smart grid sensors because, in addition to superior fault detection capability, they can:

- Predict outages before they occur

- Detect emergency overload on substation transformers

- Predict failing equipment such as underground cables

- Find phase imbalance on circuits

- Reduce technical loss

- Monitor assets like transformers or capacitor banks

- Tell if circuits are operating properly

- Deliver visibility into your worst performing circuits

- Find and resolve chronic power-quality issues

- Monitor accurate voltage for VVO/CVR applications

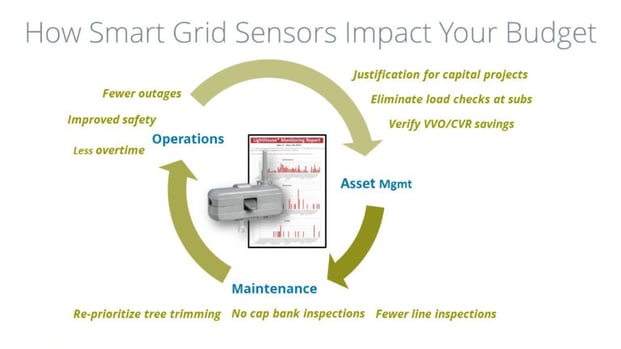

In addition to the list above, utilities are finding many more use cases and applications for Aclara smart grid sensors in their networks to continue delivering the best return on investment and support the objectives of the operations, asset management, and maintenance departments.

For example, smart grid sensors can help utilities monitor substations by determining load and voltage on the feeders or substation transformers. The sensors have configurable reports and alarms that are customizable to your transformer’s rating. With real-time overload and peak-load reporting, smart grid sensors will alert utilities when transformers are being stressed beyond capacity. Additionally, real-time phase imbalance monitoring can tell when phases are out of balance at the transformer, which can accelerate the aging process.

Additional applications of Aclara smart grid sensors

Here are some of the most popular applications of smart grid sensors:

All the real-time data provided by smart grid sensors allows the utility to eliminate the operating expense of sending crews out to substations twice a year for peak-load readings and allows the asset management department to more accurately plan capital projects. Together, this delivers significant costs savings.

When you deploy Aclara smart grid sensors at your unmonitored substations, you can also take advantage of our industry-leading fault detection capabilities to know when outages are happening in real time and where to send crews. This combined benefit of affordable substation monitoring plus fault detection is especially valuable in rural environments where crews have long drive times to find a fault. By eliminating truck rolls and crew time spend in the field, Aclara smart grid sensors can make a positive financial impact by removing operational costs and allowing utilities to deliver safe, affordable and reliable energy. They also can be used to prevent outages from occurring.

This was a short overview of just a few of the key use cases for Aclara MV Sensors. Click the button below to download our white paper describing the technical details of how to scale your SCADA architecture for distribution automation with smart grid sensors.

See the final installment of our 4-part blog series here, where we will discuss the hidden costs of fault current indicators that make them more expensive to own than sensors.