Traditional IEC 60309 pin and sleeve devices are safe and proven devices. And Hubbell should know—we introduced the pin and sleeve concept to North America decades ago and is widely accepted as the highest performing heavy duty pin and sleeve device engineered to withstand abusive and washdown environments.

In fact, Hubbell’s traditional pin and sleeve devices are among the safest out there—Hubbell has the highest UL witnessed HP ratings of an IEC pin and sleeve device and are recognized by the NEC as an approved motor disconnecting means, even under heavy load.

These devices are constantly being tested in our labs—performance tested and even torture tested.

But there is always room for better.

A couple of years back, Hubbell engineers took a hard look at the traditional IEC pin and sleeve design and thought how they could make it better.

And better starts with safer.

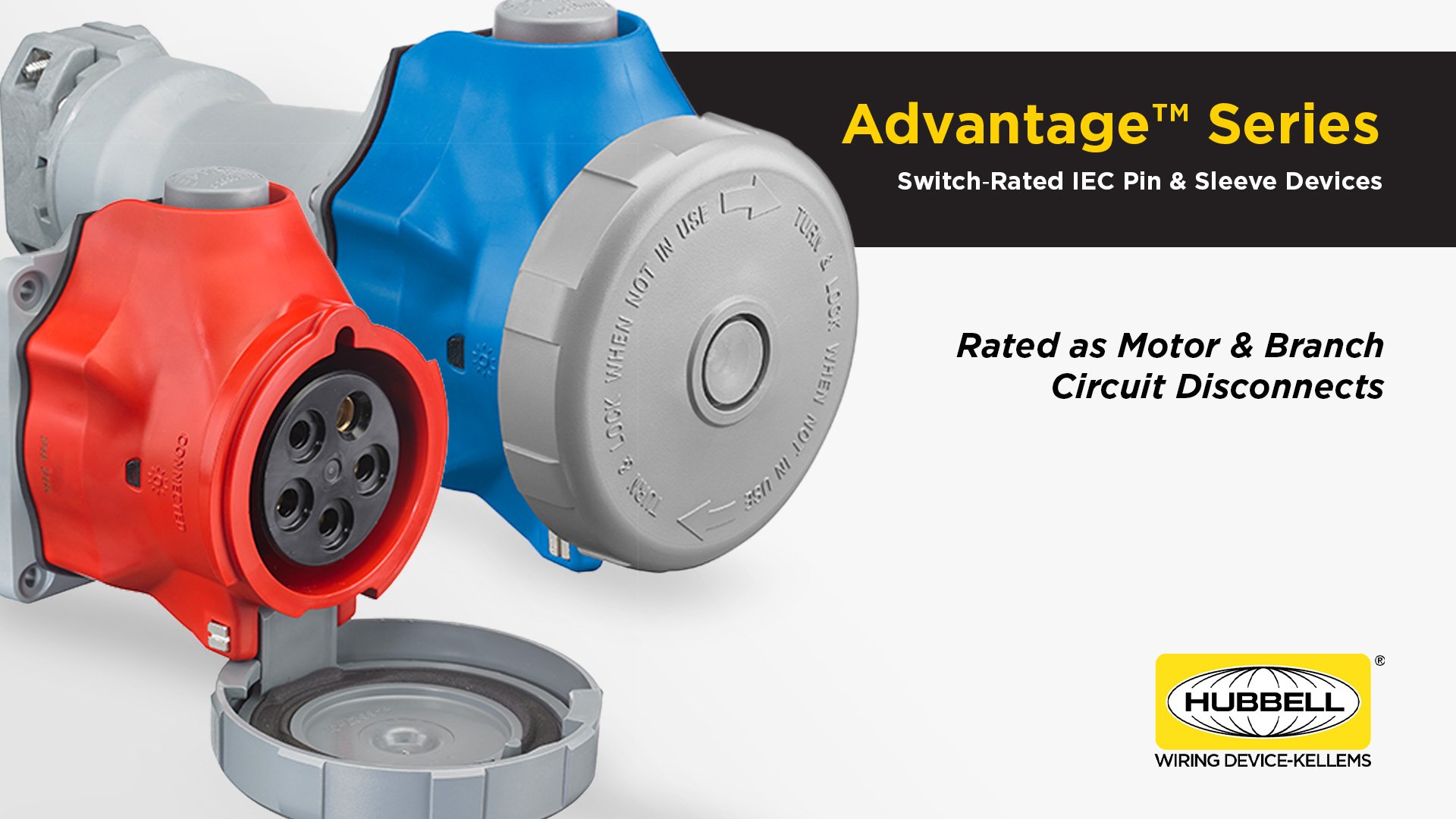

Introducing an even safer pin and sleeve design… and the only switch-rated IEC pin and sleeve connectors that can mate with the existing installed base of standard IEC plugs and inlets. Customers can now increase the safety in their facility simply by updating the female side of the connection.

The desire to raise the bar on safety even higher was the genesis of the Hubbell Advantage pin and sleeve product line. The innovative design provides the ultimate in safety for disconnecting under load. When you look at the female side of the connection it does not look much different than a standard device. What you do not realize is that the sleeves are not energized at all until a plug is fully inserted, moves the internal shuttle and brings the isolated contacts together.

Wait, how is this done? When a user mates the devices together, a leading plastic shroud on the male device “unlocks” the shuttle on the female side of the connection. It is the phase sleeves that are the game changer. They are shortened with internal isolated contacts on the bottom of the sleeve. The ground mates first, and is a continuous unswitched ground—unique in the industry. The shortened neutral and phase sleeve are still not energize yet. As the plug continues to enter the housing, a disconnect spring engages, and the contacts eventually close together and the shuttle locks into place. The sleeves in the shuttle are now energized—and a warm green LED starts to glow to let you know the device is energized and the plug cannot be removed under load.

The real magic, of course, starts when you want to disconnect the device. You need to press a prominent disconnect button, releasing the disconnect spring, breaking the connection between the internal contacts de-energizing the sleeves—before the user can remove the plug. Therefore, there is no chance of users pulling an arc or of coming into contact with live contacts.

Users who are familiar with the wide range of pin and sleeve devices used throughout industry might note that switch rated Advantage Series takes much of the functionality of motor disconnect devices and puts it all into compact package—one roughly the size of a traditional pin and sleeve housing! So, it can provide the functionality of a disconnect for cord drop applications.

Not only safer at disconnecting, but safer and better all around

As long as we’re going to redesign the concept of the pin and sleeve to provide a safety advantage, Hubbell decided we were going to provide other advantages as well. In fact, our sales force and engineers worked together to list all the customer pain points we could think of and engineer in effective solutions.

Standards are a good way to discuss performance, and Advantage, amazingly to some, meets both IEC 60309 and UL2682 which is the category for switch-rated devices , meeting the challenge of the higher testing requirements when they are conflicting. For example, the UL standard doesn’t specifically mention color coding by voltage to optimize safety when mating devices, IEC demands it, and Advantage incorporates it. And, Advantage is endurance tested to perform at 10,000 mating cycles—the highest of the two test programs—for optimum robustness and longevity in any application.

Then there’s IP69k - ensuring protection against water and dust ingress. With the Advantage series you can be vigorous with your wash-downs, and not be at all concerned about the efficacy of the plug—or the vital equipment attached to it. The Advantage series stands up to 176°F water shot at upwards of 1450 psi four to six inches away from the device at four different angles. And eight hours in the high vacuum dust chamber too. So you know you can have high confidence it will stand up to the most aggressive plant conditions and cleaning procedures—with no dirt or water getting anywhere near the energized areas.

Here’s a few other new benefits to mention quickly in this short post—the Advantage series has a design that really intelligently thinks through how it will be used, and optimizes it in many ways. For example it has minimal nooks and crannies or sharp corners so blasted dirt and debris will flow right off as opposed to getting trapped, as can be the case with some devices. And the ergonomic design and “oversized” disconnect button makes Advantage devices easy to work with, even with gloves on—solving another common pain point frequently expressed by our customers.

I mentioned the power indicator lights, showing you that the device is energized and there is no bad, lazy or otherwise compromised connection. Hubbell was the first to provide this, and you’ll see the difference, quite literally—the green glow is very visible and dramatic even from a distance, which is not always the case with other devices on the market.

Another huge benefit—Advantage devices will mate with any traditional 60309 pin and sleeve plugs and inlets. So you can start to get all these Advantage benefits without replacing your entire installed base, no matter what brand. Hubbell even rethought the positioning of the screws, placing them for optimum convenience and workability. Your technicians will notice and appreciate the difference. We were listening to them!

Hubbell launched the Advantage series with a 30 amp version, and customers loved them, leading us to release 60 and 100 amp versions. Due to additional requests alternate versions are also in the works.

Bottom line: if your organization refuses to compromise even one iota on safety—Advantage is even safer than Hubbell’s traditional pin and sleeve, and safer than anything else on the market anywhere. We invite you to compare. And with a host of performance and efficiency benefits adding even more icing on the cake, you may just want to join the growing number of industrial users who are getting the benefits of Advantage pin and sleeve devices in their operations.